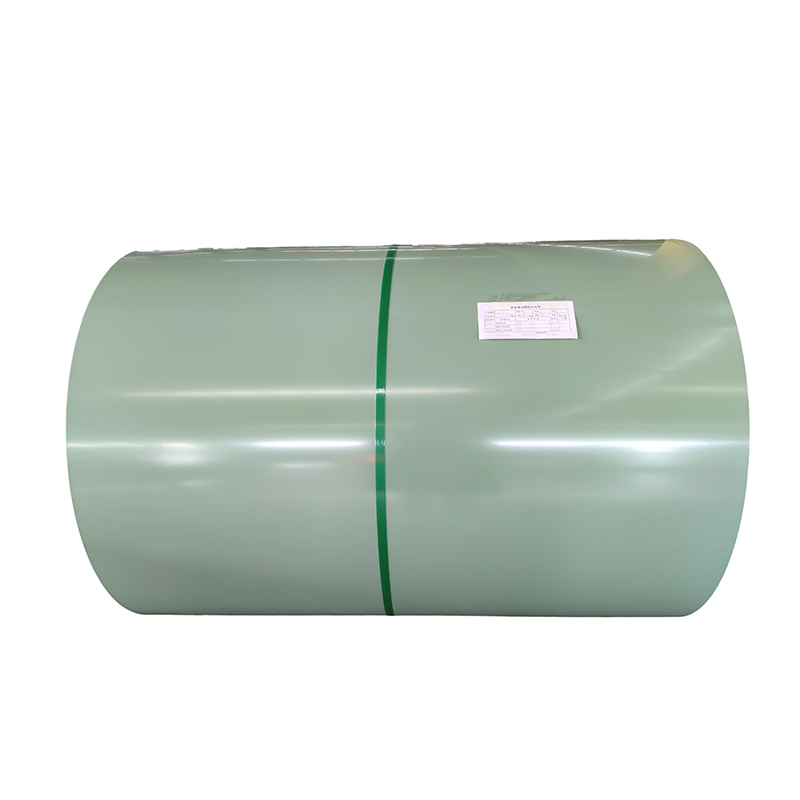

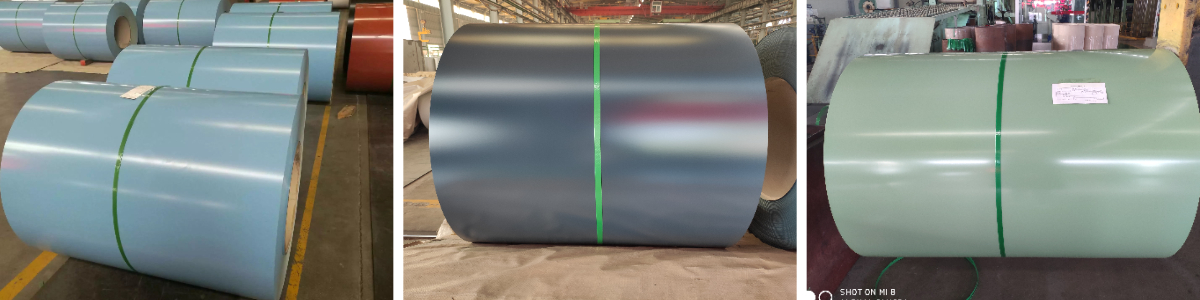

Prepainted Galvalume Steel Coil

Strong UV & Weather Resistance: Nano-silicified SMP coating delivers excellent resistance to UV light, fading, and chalking, ensuring long-lasting outdoor durability across diverse climates.

Enhanced Corrosion Protection: With salt spray resistance up to 1500 hours and compatibility with GL and ZAM substrates, the product performs well in sandstorm-prone, industrial, and coastal environments.

Excellent Scratch & Wear Resistance: Good resistance to windblown sand, surface scratching, and general abrasion makes it suitable for demanding industrial and roofing applications.

Good Processing Performance & Stable Appearance: Offers reliable bendability, coating adhesion, and surface stability, with customizable colors and gloss levels to meet various architectural and industrial requirements.

Silicone Modified Polyester (SMP) Color Coated Sheet

Product Introduction

Xinghan's SMP color coated sheets utilize galvanized, galvalume, or zinc-aluminum-magnesium substrates, combined with a highly durable nano-silicified resin coating. They offer excellent UV resistance, preventing chalking and chemical erosion, ensuring good outdoor durability for buildings under various climatic conditions.

Product Advantages

Excellent corrosion resistance

Superior anti-fading and anti-chalking properties

Good resistance to windblown sand, sunlight, and scratching

Outstanding wear resistance

Product Specifications

Sheet Thickness: 0.17mm - 1.0mm

Sheet Width: 650mm - 1250mm

Paint Type: SMP

Color: Customizable according to customer requirements, refer to RAL color cards and standard color cards

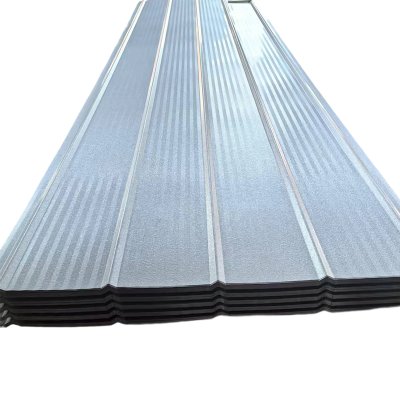

Substrate Type: Embossed Galvanized, Smooth Galvanized, Galvalume (GL), Zinc-Aluminum-Magnesium (ZAM)

Coating System: Two-coats-two-bakes process, customizable based on customer needs

Coating Thickness: Standard 20–25µm / 5–10µm

Coating Performance

Pencil Hardness: ≥ F

Gloss: Low-gloss ≤ 40%, Medium-gloss 40–70%, High-gloss > 70%

T-Bend: Low ≤ 5T, Medium ≤ 3T, High ≤ 1T

MEK (double rubs): ≥ 100

Reverse Impact: ≥ 9 J

Salt Spray Resistance: ≥ 1500 h

Execution Standards

GB/T12754, ASTM A792

Product Strength Grades

G250, G280, G300, G320, G345, G350, G550

Recommended Applications

Suitable for exterior walls, interior walls, and roofing of buildings in industries such as thermal power, mining, cement, and aggregate, as well as in areas with severe sandstorms.

Performance Tests

| Test Item | Test Result |

Pencil Hardness: GB/T13448 | Min. HB |

T-Bend: GB/T13448 | Max. 3T |

Cross-Cut Adhesion: GB/T13448 | No coating peeling |

Reverse Impact: GB/T13448 | Min. 9J |

Water Contact Angle: | ≤ 60° |

Carbon Black Test: | Color Difference: ≤ ΔE 0.7 |

Humidity Resistance: 100% Relative Humidity, 1000 hours GB/T13448 | No coating peeling |

Salt Spray Test: 1500 hours ASTM B117 | Undercut ≤ 3mm, Blistering Rating F8 |

UV Accelerated Aging Test: 2000 hours GB/T13448 | Color Difference: ≤ ΔE 3, Chalking: < 2 |

Water Immersion Test: 38℃ 168 hours GB/T13448 | Essentially no color difference and no blistering |

Abrasion Resistance: GB/T13448 | Total Sand: 35±5 Liters |

Exposure Test: GB/T13448

Coating Integrity: 15 years

Color: 15 years exposure, no significant color change or not exceeding ΔE 7 Hunter units; Chalking Resistance: 15 years exposure, no significant color change or not below Rating 6

Dirt Pick-up Resistance: 5 years no significant color change or dirt staining

Precautions for On-site Installation of Color Coated Panels

1. Pre-Installation

Before installation, check the color and surface quality of the color coated panels. If the coating has been damaged during previous processing, use with caution. During installation, avoid dragging, scratching, bending, or denting the panels. When walking on color coated panels or their fabricated components, wear shoes with smooth, soft soles free of debris such as small stones or metal chips. Distribute weight evenly and be mindful of foot placement to prevent denting or deformation of the panels or fabricated parts.

2. Corrosion Prevention

When connecting color coated panel components with fasteners such as bolts or rivets, ensure the corrosion resistance of the fasteners matches that of the panels to prevent premature corrosion of the fasteners, which could become accelerated corrosion sources. Also, consider the potential difference between the fastener material and the color coated panels to avoid galvanic corrosion. The use of galvanized or aluminum fasteners is recommended. Carefully select and use installation tools to avoid scratching the panels. Design fastening locations appropriately; when bolting, fasten to a moderate tightness to avoid water leakage due to looseness or panel deformation due to over-tightening.

3. pH of Chemical Products

When using chemical products such as adhesives or sealants with color coated panels, pay attention to their pH level. Use neutral chemical products to avoid corrosion of the coating by acidic or alkaline substances, which could affect the service life of the panels.

4. Dryness

Consider the installation angle and position of color coated panel components. Prolonged water retention can reduce coating adhesion. Therefore, ensure during design and installation that water can drain promptly and avoid ponding. Materials such as copper, lead, graphite, unprotected steel plates, or untreated wood must not come into direct contact with color coated panels, as these substances can react with the substrate or coating, reducing the panel's service life.

5. Use the Same Batch for a Single Project

Metallic color coated panels achieve their unique appearance by adding mica or aluminum powder particles to the coating. While these particles create a distinctive look, they also cause directional alignment of the pigments, leading to visual differences. To prevent color variation, all panels used in the same project should be installed aligned in the same direction after profiling. It is recommended to use color coated panels from the same batch for a single project.

6. Handling Scratches

This defect typically appears as scratches or particles from the back paint adhering to the surface of the color-coated steel sheet. It is caused by improper handling, insufficient curing of the coating, and irregularities on the panel surface. The degree of coating curing, hardness, and lubricity influence the occurrence of scratches. Good roll lubrication and appropriate back paint will help reduce such defects. Sometimes, applying a transparent, peelable film to the surface of the color-coated sheets can prevent handling scratches. Hoisting of bundles within the factory may also cause scratches. To avoid scratches due to bending, hoisting equipment for long bundles should support most of the bundle's length, and bundles must be secured both longitudinally and transversely. During road transport, ensure that bundles do not come into direct contact with other objects, such as structural components. When using forklifts for handling, operate carefully to prevent excessive bending or scratching of the color-coated sheets.

7. Installation Burrs

Metal debris, drill chips, cutting scraps, and other metal objects (such as rivets and fasteners) must never be left on the surface of color-coated sheets, as these residues can cause rust stains after corrosion. Any such residues should be swept off the roof immediately upon discovery, or at least cleaned up at the end of each workday. Avoid walking on the sheets to prevent damage to the paint film. In strict applications, the building should be inspected within two weeks after installation to remove any residues that may rust. Timely removal of residues will help maintain the roof's appearance over the long term.

8. Peelable Film

Some color-coated sheets are covered with a specially designed transparent organic film. This film protects the coating from scratches during storage and transportation but must be removed immediately after installation. Sunlight exposure will enhance the adhesion between the organic film and the sheet surface, making removal more difficult.

9. Cutting

Pre-cut sheets should be used whenever possible to avoid on-site cutting. If cutting is necessary, tools such as straight snips, curved snips, saws, and manual shears can be used. All on-site cutting must not damage the coating or plating of the color-coated sheets and should result in clean edges. Shears must be kept sharp to minimize burrs. During shearing, the sheet should be positioned with the surface facing up so that any burrs form on the back side.

Cutting should not be performed on other color-coated sheet surfaces. If power cutting or drilling is required, apply tape or rags around the drilling area and near the cut to prevent hot chips from damaging the coating. Avoid using tools such as grinding wheels, hacksaws, or flame cutting, as they can damage the steel sheet's plating and coating.