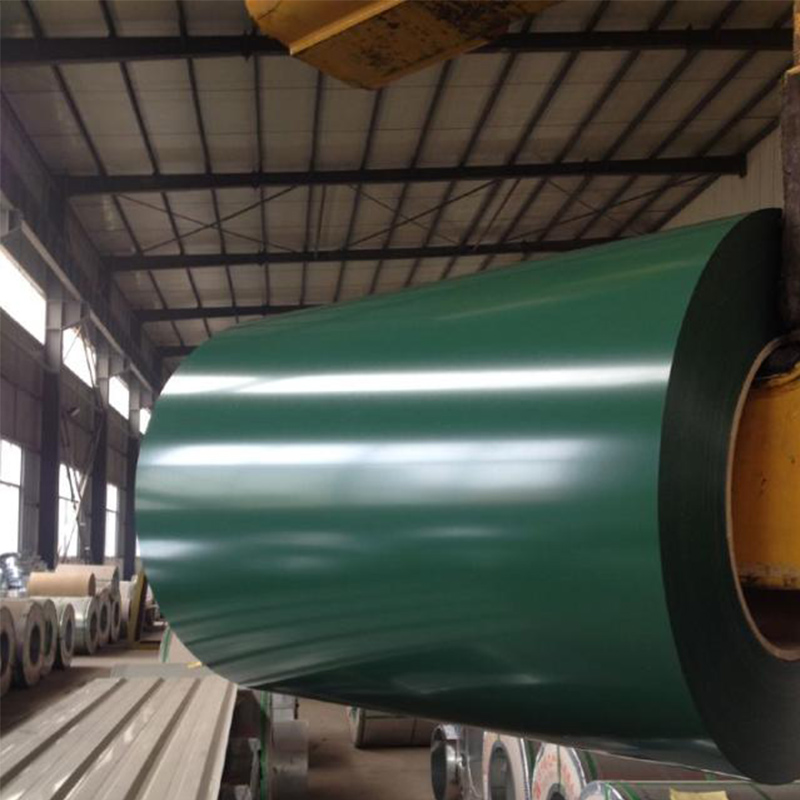

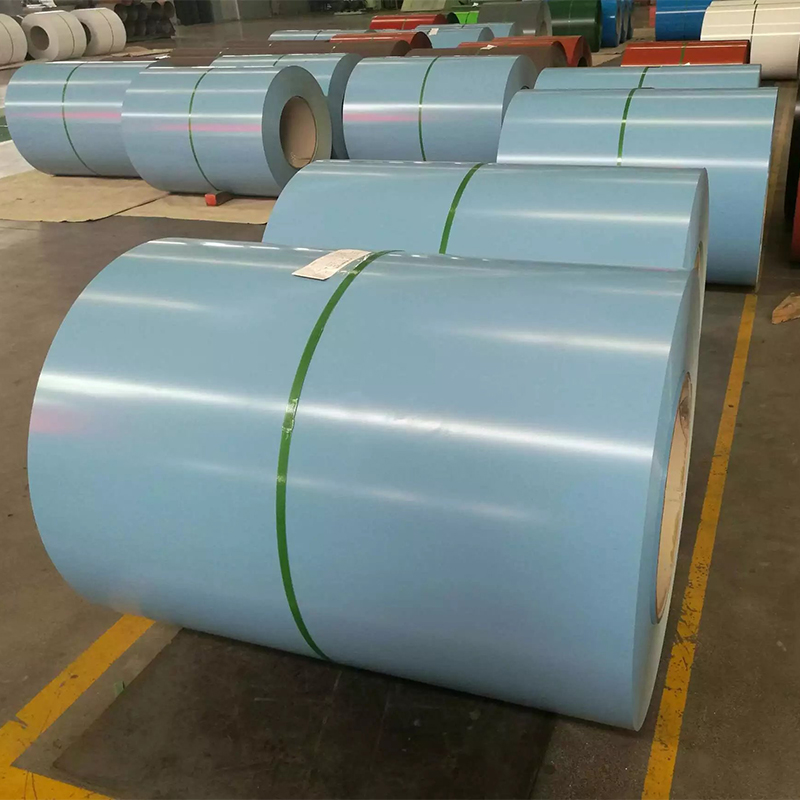

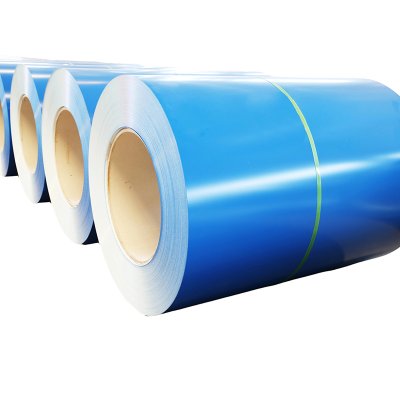

Prepainted Coil

Reliable Weather & Corrosion Resistance: PE coating provides solid protection against corrosion, fading, and chalking, ensuring stable performance in general outdoor environments.

Good Flexibility & Processing Performance: Excellent bendability, strong adhesion, and impact resistance make the sheets easy to form, cut, and install without coating damage.

Versatile Color & Gloss Options: Available in multiple standard colors with full customization based on RAL color cards; supports low, medium, and high gloss levels for diverse architectural needs.

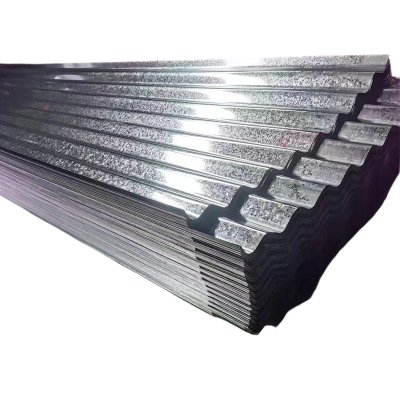

Cost-Effective & Widely Applicable: With balanced durability and affordability, PE color coated sheets are widely used in roofing, wall cladding, public facilities, and large-scale international projects.

Polyester (PE) Color Coated Sheet

Product Advantages

Excellent corrosion resistance; Outstanding anti-fading and anti-chalking properties; Superior weather resistance; Excellent flexibility and processing performance.

Product Width

650mm-1250mm

Product Color

White Gray, Sea Blue, Scarlet Red, Wall Gray, and Silver Gray are standard colors. Other colors can be customized according to customer requirements, referencing RAL color cards and standard color cards.

Coating System

Produced using a two-coat-two-bake process, customizable based on customer needs.

Coating Performance

Pencil Hardness: ≥ F

Gloss (%): Low ≤40, Medium 40-70, High >70

T-Bend: Low ≤5T, Medium ≤3T, High ≤1T

MEK (double rubs): ≥100

Reverse Impact (J): ≥9

Salt Spray Resistance (h): ≥1000

Product Strength Grades

G250 / G280 / G300 / G320 / G345 / G350 / G550

Performance Test

Test Item | Test Result |

Pencil Hardness: GB/T13448 GB/T12754 | Min. F |

T-Bend: GB/T13448 | Max. 4T |

Cross-Cut Adhesion: GB/T13448 | No peeling of paint film |

Reverse Impact: GB/T13448 | Min. 9J |

Chemical Resistance: GB/T13448 | No fading or bubbling |

Humidity Resistance: 95%-100% Relative Humidity, 1000 hours GB/T13448 | No peeling of paint film |

Salt Spray Test: 1000 hours ASTM B117 | Undercut ≤ 3mm |

UV Accelerated Aging Test: 1500 hours GB/T13448 | Color Difference: ≤ ΔE 3, Chalking: < 2 |

Water Immersion Test: 38℃ 168 hours GB/T13448 | Essentially no color difference and no blistering |

Abrasion Resistance: GB/T13448 | Total Sand: 35±5 Liters |

Exposure Test: GB/T13448 | Coating Integrity: 10 years |

Product Application Scenarios

Hamad International Airport, Qatar | Jakarta-Bandung High-Speed Railway Project, Indonesia | Lagos International Airport | Indofood Sukses Makmur (Indofood) |

Wuhan Leishenshan Hospital | Wuhan Huoshenshan Hospital | Tsing Yi Mobile Cabin Hospital, Hong Kong | San Tin Mobile Cabin Hospital, Hong Kong |