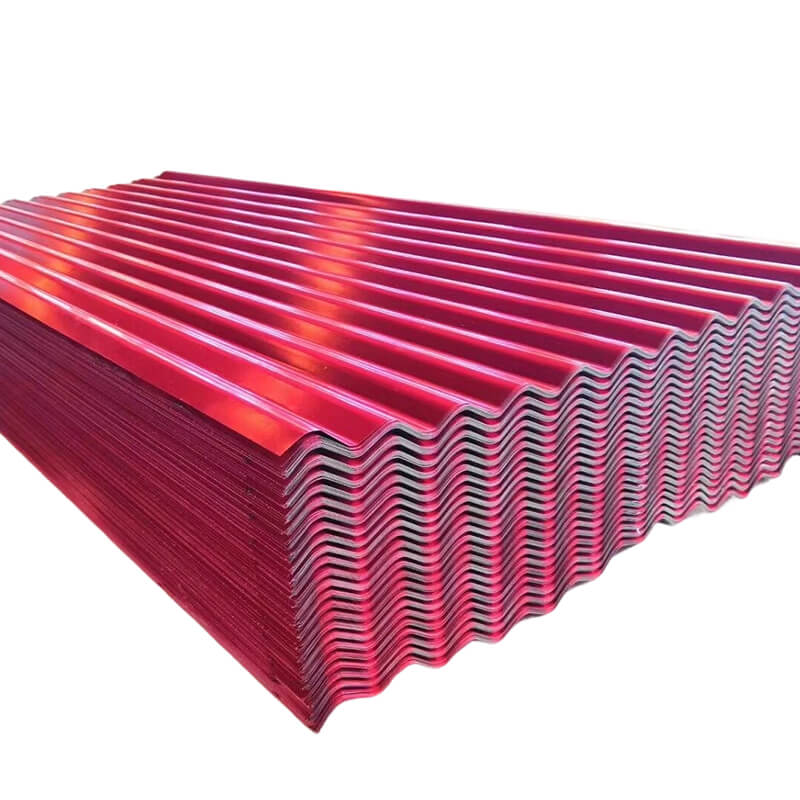

Prepainted Galvalume

Superior Weather & UV Resistance: The HDP coating system, made with high–molecular-weight polyester resin, delivers long-lasting outdoor durability, excellent color retention, and strong resistance to UV exposure and chalking.

Excellent Coating Strength & Adhesion: The two-coat, two-bake process ensures a firm, uniform coating layer with strong adhesion, high hardness, and outstanding resistance to wear, impact, and corrosion.

Versatile Processing & Wide Application Range: With good formability, flexibility, and stable mechanical performance, the sheets are ideal for bending, cutting, and shaping—suitable for industrial, coastal, high-humidity, and high-UV environments.

Product Introduction

The high durability polyester (HDP) color-coated sheet is produced using an advanced, weather-resistant polyester coating system. Formulated with high–molecular-weight HDP resins and supported by a stable galvanized substrate, the coating resists photodegradation and chalking. With superior color retention, UV resistance, and anti-chalking performance, it stands out as a premium product in the color-coated sheet market.

Product Advantages

Features include high-molecular-weight resins, outstanding outdoor durability, strong chalk resistance, excellent coating adhesion, cost-effectiveness, superior weatherability and abrasion resistance, robust UV protection, and good processability.

Product Specifications

Sheet Thickness: 0.17mm – 1.0mm

Sheet Width: 650mm – 1250mm

Paint Type: HDP

Color: Customizable per customer requirements; compatible with RAL and standard color charts

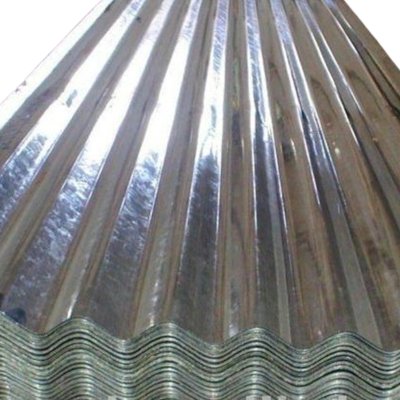

Substrate Options: Embossed, Smooth, Galvalume (GL), Zinc-Aluminum-Magnesium (ZAM)

Coating System: Two-coat, two-bake process; adjustable based on customer needs

Coating Thickness: Standard 20–25 μm (top) / 5–10 μm (back)

Coating Performance

Pencil Hardness: ≥ HB

Gloss (%): Low ≤40 / Medium 40–70 / High >70

T-Bend: Low ≤5T / Medium ≤3T / High ≤1T

MEK (double rubs): ≥200

Reverse Impact (J): ≥9

Salt Spray Resistance (hours): ≥2000

Applicable Standards

GB/T 12754 / ASTM A792

Available Strength Grades

G250 / G280 / G300 / G320 / G345 / G350 / G550

Recommended Applications

Ideal for chemical, metallurgical, and power industries; coastal or humid regions; high-UV environments; heavily polluted or corrosive areas; and building exteriors requiring strong corrosion resistance. It is also suitable for standard industrial, commercial, public, and residential projects exposed to intense UV radiation or requiring long-lasting performance.

Maintenance of Color Coated Sheets for Buildings

Proper maintenance can significantly extend the service life of color-coated sheets. Although they last much longer than manually painted panels, periodic cleaning is still necessary. Cleaning removes accumulated corrosive substances and helps preserve the building’s appearance.

Areas commonly requiring cleaning include supports, the underside of drip edges, warehouse door panels, and the grooves on the back of drip-edge panels.

01. Cleaning

Regular cleaning is recommended to remove dust, debris, and standing water, generally once every six months. In coastal areas with high salt exposure or industrial zones with heavy particulate levels, cleaning frequency should be increased accordingly.

Clean water is typically sufficient. For stubborn stains, a mild soap or neutral detergent may be applied using a soft cloth, sponge, soft brush, or low-pressure spray. Clean from top to bottom to avoid streaking or shiny patches, then rinse thoroughly with clean water.

Before applying any detergent, test it on an inconspicuous area to ensure compatibility. After cleaning, remove all detergent residue completely.

02. Touch-Up Painting

If scratches occur during installation or use, touch-up coating may be required. Poor or excessive touch-up work can damage the overall appearance.

During routine use, periodic inspection and maintenance are recommended. Areas with aged or damaged coatings can be repaired through touch-up painting. Before applying touch-up coatings, clean all contaminants with a neutral cleaner and sand the area to remove rust. Apply primer only when the surface is clean and dry, followed by a topcoat.

Ensure that all contaminants, sanding dust, and rust are fully removed before priming. Touch-up pens are not advised for large areas, and aerosol or spray products are not recommended for repairing scratch-type defects.

Quality Commitment

Xinghan Coating has passed the GB/T19001-2016 and ISO9001:2015 quality management certifications and has established a comprehensive quality assurance system.

Under this complete system, every stage—from order placement, order processing, product design, raw material procurement, production planning, manufacturing, quality control, testing and inspection, to product packaging, warehousing, and shipment—follows standardized procedures.

Through an integrated production and sales computer management system, work efficiency is improved and product quality is fully guaranteed.

Quality Inspection

Xinghan Coating's color-coating production lines are equipped with a wide range of advanced online testing instruments to ensure and enhance product quality.

In addition, a complete set of performance testing equipment and methods is in place to conduct routine inspections and performance evaluations of color-coated products, ensuring that product quality consistently remains at the leading level within the domestic industry.