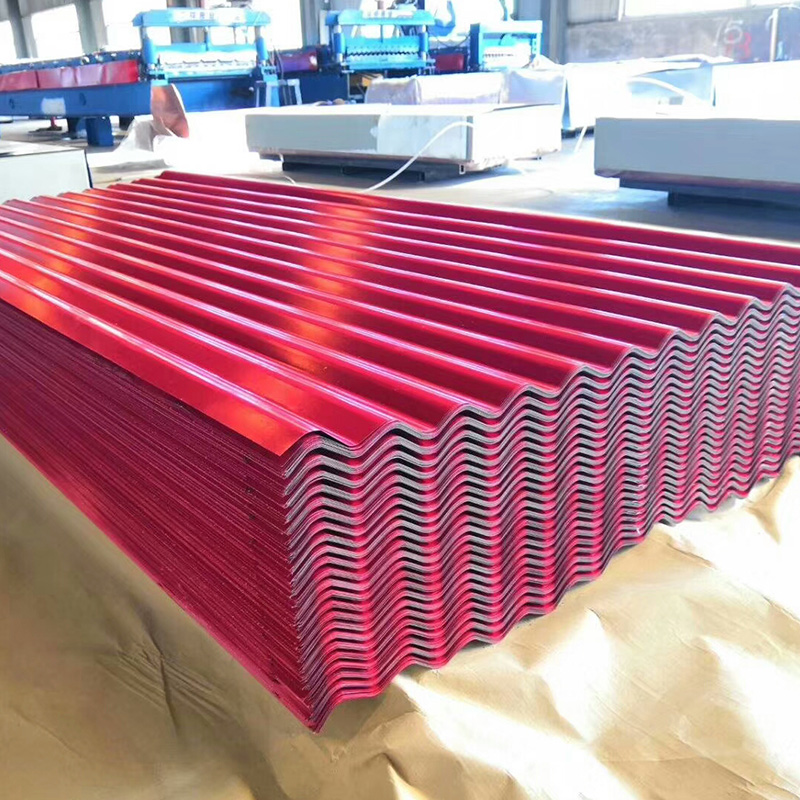

Pre Painted Galvalume Corrugated Sheet

Excellent Weather & UV Resistance: HDP coating delivers long-lasting color stability, anti-chalking performance, and strong outdoor durability.

Strong Mechanical Performance: High hardness, strong adhesion, good bendability, and easy processing without coating damage.

High Corrosion Resistance: Salt spray ≥2000 hours; suitable for coastal, chemical, and high-pollution environments.

Cost-Effective & Customizable: Offers premium performance at a competitive cost with flexible options in color, gloss, thickness, and substrate types.

High Durability Polyester (HDP) Color Coated Corrugated Sheet

Product Introduction

The high durability polyester (HDP) color coated sheet undergoes a high-weatherability polyester coating system. Utilizing HDP polyester material with high molecular weight resin and stable galvanization, it is not prone to photolysis or chalking. It offers excellent color retention, UV resistance, and anti-chalking properties, positioning it as a premium product in the color coated sheet market.

Product Advantages

High molecular resin, excellent outdoor durability and chalk resistance, strong coating adhesion, cost-effective, high weatherability, high wear resistance, strong UV resistance, easy to process.

Product Specifications

Sheet Thickness: 0.17mm - 1.0mm

Sheet Width: 650mm - 1250mm

Paint Type: HDP

Color: Customizable according to customer requirements, refer to RAL color cards and standard color cards

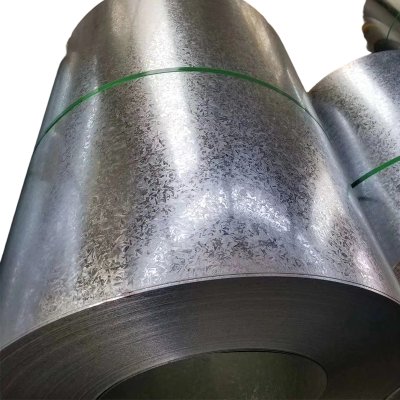

Substrate Type: Embossed, Smooth, Galvanized Nickel (GL), Zinc-Aluminum-Magnesium (ZAM)

Coating System: Two-coats-two-bakes process, customizable based on customer needs

Coating Thickness: Standard 20-25um / 5-10um

Coating Performance

Pencil Hardness: ≥HB

Gloss (%): Low ≤40 / Medium 40-70 / High >70

T-Bend: Low ≤5T / Medium ≤3T / High ≤1T

MEK (double rubs): ≥200

Reverse Impact (J): ≥9

Salt Spray Resistance (h): ≥2000

Execution Standards

GB/T12754 / ASTM A792

Product Strength Grades

G250 / G280 / G300 / G320 / G345 / G350 / G550

Recommended Applications

Suitable for industries such as chemical, metallurgy, and power; coastal and humid areas; high UV radiation regions; severely polluted and corrosive environments; and buildings requiring high corrosion resistance for exterior walls, as well as conventional industrial, commercial, public, and civil constructions exposed to intense UV radiation (including applications demanding long-lasting and durable performance).

Xinghan Color Coated Sheets - Storage

Products should be stored indoors in a dry and well-ventilated environment to avoid open-air storage.

In areas with significant temperature fluctuations, products are highly prone to condensation.

Products should be stored in a clean and tidy environment, avoiding invasion by various corrosive media.

It is not recommended to store large quantities of products in factory areas with high sulfur dioxide levels, and the storage period for already stored products should be minimized as much as possible.

Horizontal coils should be placed on rubber mats, wooden blocks, racks, or other supports, with the band lock facing upwards. They must not be placed directly on the ground or on transport vehicles.

Products must be kept dry and absolutely avoid being rained on or soaked.

To prevent crushing damage, steel coils are generally not stored stacked. If storage space is limited and stacking is necessary, the number of layers must be strictly limited, with heavier and larger coils placed at the bottom.

The mechanical properties and some coating properties (such as pencil hardness, T-bend value, impact energy, etc.) of color-coated sheets may change over prolonged storage periods. The First-In-First-Out (FIFO) principle should be followed during use.

The storage area floor should be flat, free of hard objects, and have sufficient load-bearing capacity.

The storage area should have sufficient space for the operation of handling equipment.

The storage locations for steel sheets and coils should be arranged logically for easy access, minimizing unnecessary movement.

Maintenance of Color Coated Sheets for Construction

Maintenance of color coated sheets can extend their service life. Although the lifespan of color coated building panels is significantly longer than that of hand-painted panels, they still require thorough cleaning. Cleaning helps remove accumulated corrosive substances and maintains the building's aesthetic appearance.

Areas of color coated sheets that require cleaning include supports, the underside of drip eaves, warehouse door panels, and the grooves on the back of drip eaves panels.

01 Cleaning

It is generally recommended to clean the surface of color-coated sheets regularly to remove dust, debris, and standing water, with a suggested cleaning frequency of once every six months. In coastal areas with high salt fog or industrial regions with heavy dust, the cleaning frequency should be increased based on site conditions.

In most cases, rinsing with clean water is sufficient. For stains that cannot be removed by rinsing alone, a mild soap solution or neutral detergent can be used with a soft cloth, sponge, soft-bristled brush, or low-pressure spray nozzle. Clean the sheet surface from top to bottom to avoid streaks and the creation of shiny spots. Rinse immediately with clean water after stain removal.

Before using any detergent, test it on a small, inconspicuous area to confirm it causes no damage. After cleaning, ensure all detergent residue is thoroughly removed from the surface of the color-coated sheets.

02 Touch-up Painting

If scratches occur during installation or use, touch-up painting of the damaged areas may be necessary. Improper or excessive touch-up painting may damage the entire surface.

During subsequent use, regular inspection and maintenance should be carried out. Areas with aged or damaged coatings can be treated with touch-up painting. Before touching up, first clean surface contaminants with a neutral cleaner, then sand to remove any rust layer. Subsequently, apply primer in a clean and dry condition, followed by the topcoat. Before formally applying the primer, it is essential to thoroughly remove all contaminants, sanding dust, and rust spots. It is not recommended to use touch-up pens for large areas or to employ aerosol or spray products for repairing scratch defects.