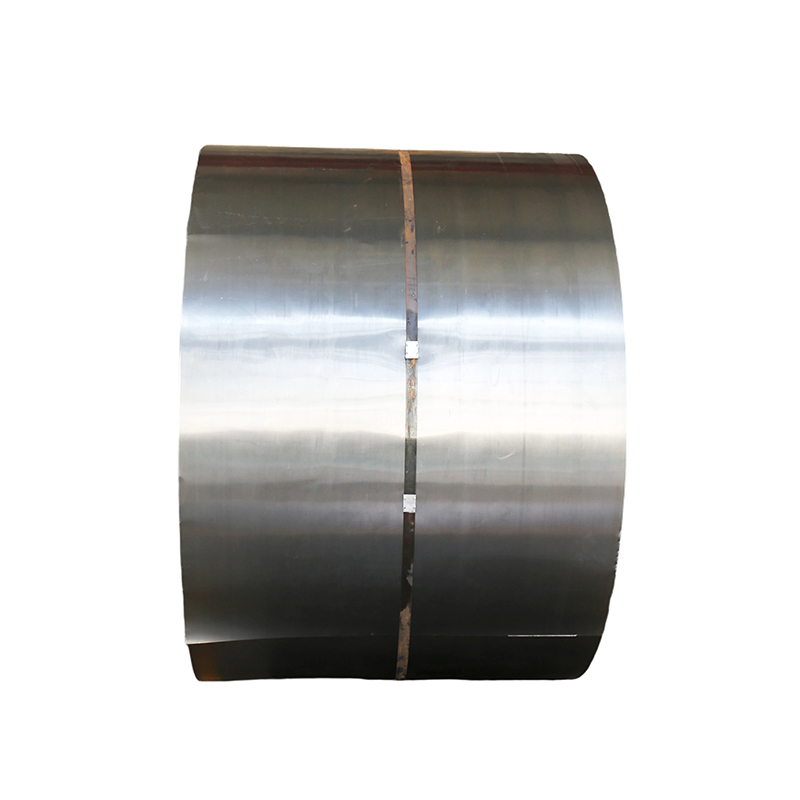

Cold Rolled Coil

High Precision & Superior Surface Quality: Cold rolling ensures uniform thickness, excellent dimensional accuracy, and a smooth, clean surface ideal for precision fabrication.

Outstanding Mechanical Performance: The material offers high strength, excellent formability, and stable mechanical properties—suitable for deep drawing, bending, and complex shaping.

Reliable Production & Consistent Quality: Seven advanced automated rolling units and a fully equipped testing center ensure consistent quality that meets or exceeds GB/T standards.

Wide Industrial Adaptability: Its corrosion resistance, durability, and precision make it suitable for demanding applications in construction, appliances, automotive, containers, and mechanical and electrical equipment.

Cold-rolled coil is manufactured by cold rolling stainless steel sheets, producing a smooth, consistent surface with precise thickness and excellent dimensional accuracy. This material provides outstanding corrosion resistance, high strength, and excellent formability, making it ideal for deep drawing, bending, and other complex fabrication processes. Cost-effective and practical, it is widely applied in construction, home appliances, automotive parts, container production, mechanical and electrical equipment, and various other industrial sectors.

Coldroll lines

The facility operates seven single-machine reversible cold rolling units, utilizing advanced cold rolling technologies from both domestic and international sources to ensure product quality meets or exceeds GB/T708-2019 and GB/T710-2008 standards. To maximize production efficiency, each unit is designed with state-of-the-art structures and the highest level of automation available. The rolling mills are categorized into three types—1150, 950, and 1450—with a total annual production capacity of 1 million tons.

Available range and production capacity

Production Line | Highest Speed (m/min) | Thickness (mm) | Width (mm) | Coil ID (mm) | Annual Capacity (MT) |

950 Rolling | 480 | 0.12 - 0.8 | 650 - 950 | 508 | 100,000 |

1150 Rolling | 1200 | 0.08 - 3.0 | 700 - 1050 | 508 | 300,000 |

1450 Rolling | 1200 | 0.18 - 3.0 | 750 - 1300 | 508 | 600,000 |

Test center

The testing center spans over 1,500 square meters and is staffed by 10 technical experts and professional testing personnel. Equipped with advanced testing instruments, it is capable of analyzing steel chemical composition, assessing mechanical properties, examining microstructures, and evaluating surface and coating performance, providing a reliable guarantee of product quality. Additionally, the center supports product development and optimization. A separate testing facility specializes in pressure, thermal, and dimensional calibration, ensuring the accuracy of production monitoring instruments and maintaining consistent product quality.

Product Application Cases

Qatar Hamad International Airport Phase B expansion project

Hamad International Airport, formerly known as the New Doha International Airport, is located in the Middle East, Qatar's capital city of Doha, an international airport. Hamad International Airport put into operation in 2014, is one of the most advanced facilities in the Middle East, the largest passenger throughput of the aviation hub. The Phase B expansion of the airport is under way, including the construction of 11,000 square metres of new retail and dining areas and a 10,000 square metre indoor garden, as well as a new cargo terminal with a capacity of 60 million passengers per year. Once completed, the airport's annual passenger capacity will increase to 70 million, with the Middle East expected to double by 2040, according to the latest International Air Transport Association data.

Indonesia Jakarta-Bandung high-speed rail project

Connecting Jakarta, the capital of Indonesia, and Bandung, the fourth largest city in Indonesia, the Jakarta-Bandung high-speed Railway is the first high-speed railway in Southeast Asia and the first high-speed railway construction project with the whole system, all elements and the whole industrial chain of China's high-speed railway overseas.

In 2016, the Jakarta-Bandung high-speed rail project was officially launched, and under the personal promotion of the heads of state of China and Indonesia, the construction of the Jakarta-Bandung high-speed rail has continued to advance and made significant progress. As a landmark project of high-quality Belt and Road cooperation between China and Indonesia, the Jakarta-Bandung high-speed rail is a vivid illustration of the rich connotation of building a China-Indonesia community of shared future, and a vivid illustration of China and its neighbors working together under the principle of extensive consultation, joint contribution and shared benefits to deepen mutually beneficial and win-win cooperation.

Recently, the Jakarta-Bandung high-speed railway with a total length of 142 kilometers has reached 350 kilometers per hour for the first time, and the maximum speed reached 386km/h, marking that the Jakarta-Bandung high-speed railway has reached the design speed standard. The completion of the railway has witnessed the vigorous development of bilateral relations and become a vivid epitome of cooperation between China and economies in the Asia-Pacific region.