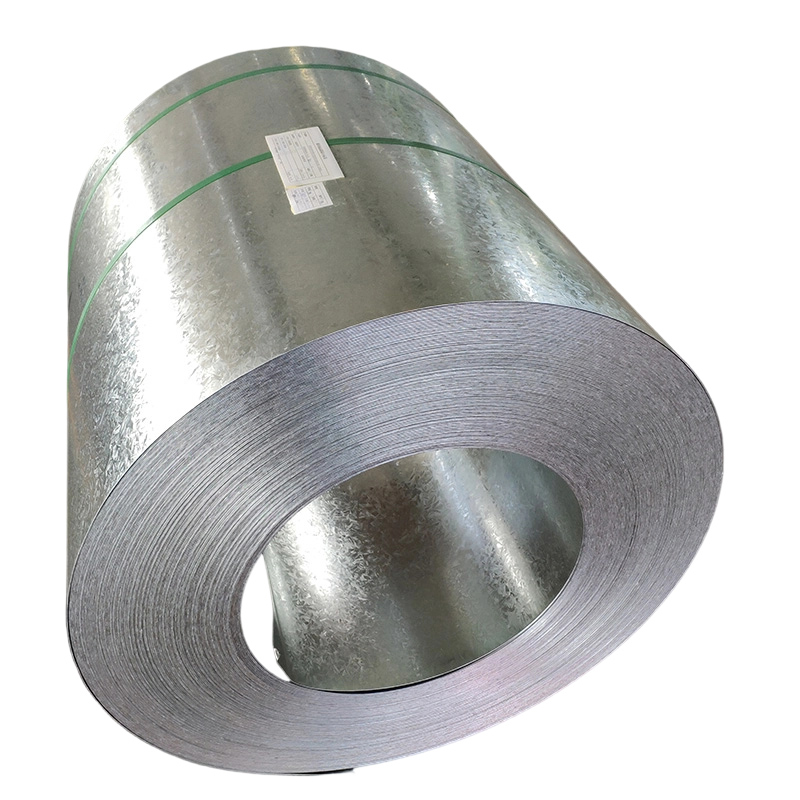

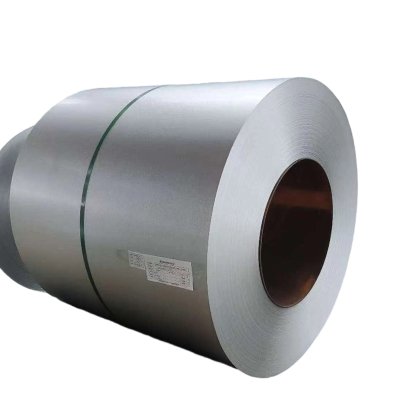

Galvanized Steel Spangle

Superior Corrosion Protection & Long Service Life: The hot-dip zinc coating forms a strong barrier layer that resists rust, enhances durability, and provides excellent surface quality suitable for deep processing.

High Strength with Cost Efficiency: Wide grade range from mild to S550GD structural steel allows thinner, lighter components at the same strength level—reducing material costs while maintaining performance.

Large-Scale, Stable Production Capacity: Three advanced galvanizing lines (0.1–3.0 mm, 700–1300 mm, ≥20 GSM) with an annual capacity of 650,000 MT ensure reliable supply, consistent quality, and flexible customization.

Galvanized steel spangle is produced by continuously dipping cold-rolled steel coils into molten zinc, forming a fused protective zinc layer on the surface. This composite material delivers excellent corrosion resistance, extends service life, offers smooth surface quality, supports deep processing, and provides an economical, practical solution widely used in construction, home appliances, automotive, shipbuilding, containers, and electromechanical industries.

Galvanized steel, a coiled cold-rolled steel plate is continuously dipped in a plating tank with molten zinc, and a layer of zinc is fused on the surface of the anti-corrosion material.

It is a steel-based composite material, which can effectively prevent the corrosion of steel, prolong the service life, has excellent corrosion resistance, good surface quality, is conducive to deep processing, economical and practical, and is widely used in construction, household appliances, vehicles and ships, container manufacturing, mechanical and electrical industries and other fields.

Performance Parameter

Type of Products | Grade / Material | Thickness (mm) | Width (mm) | Uses and Characteristics |

Mild and Ultra-Low Carbon Steels | SGCC, DX51D, DX52D | 0.1 - 3.0 | 700 - 1300 | Construction steel and general appliance steel. |

Mild and ultra-low carbon steels | DX53D | 0.3 - 1.0 | 700 - 1300 | For deep drawing applications. Offers greater ductility than deep drawing grades, suitable for manufacturing components requiring extra-deep stamping forming and more complex processing. |

Structural Steel | S220GD+Z, SS33, SGC340 | 0.4 - 3.0 | 700 - 1300 | These products feature good corrosion resistance and workability. At the same strength level, they can be made thinner, resulting in lighter components and more economical costs. Primarily used in the construction field, especially for steel structure buildings. |

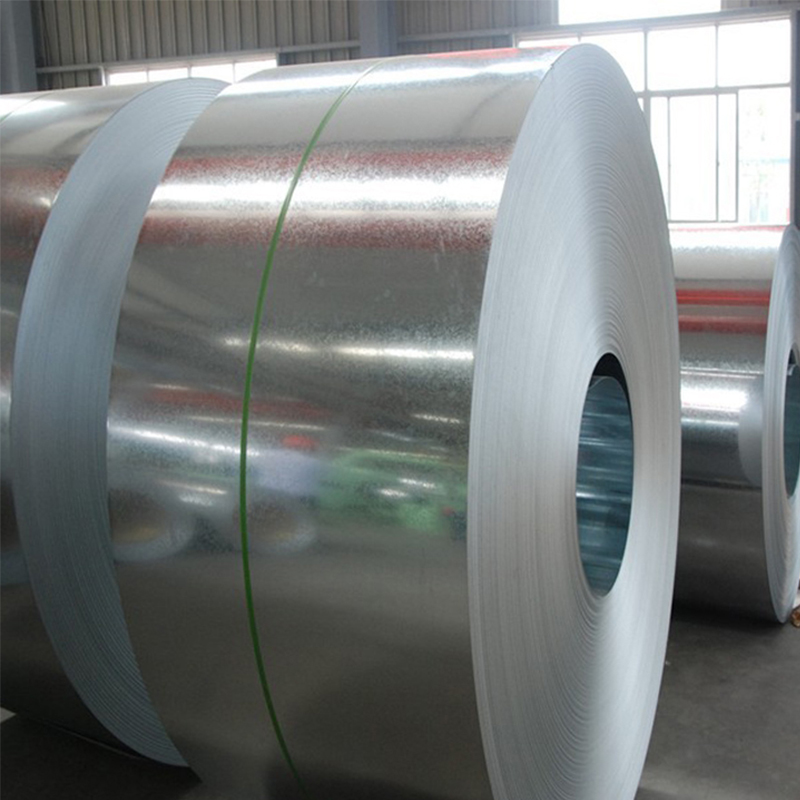

Galvanized production line with spangle

The galvanized production line is designed and constructed by a well-known domestic technology company. The production line is a continuous strip steel annealing and galvanizing unit, which has the functions of annealing reduction, galvanizing, tension leveling, and skinning. The production specifications are 0.1-3.0mm thickness, 700-1300mm width. The company has three hot-dip galvanizing production lines with a designed production capacity of 650,000 tons per year.

Available range and production capacity

Production Line | Thickness (mm) | Width (mm) | Zinc Coating (GSM) | Surface Treatment | Annual Capacity (MT) |

Gl line with spangle | 0.1 - 3.0 | 700 - 1300 | ≥20 | Chromated, AFP, oiled | 650,000 |