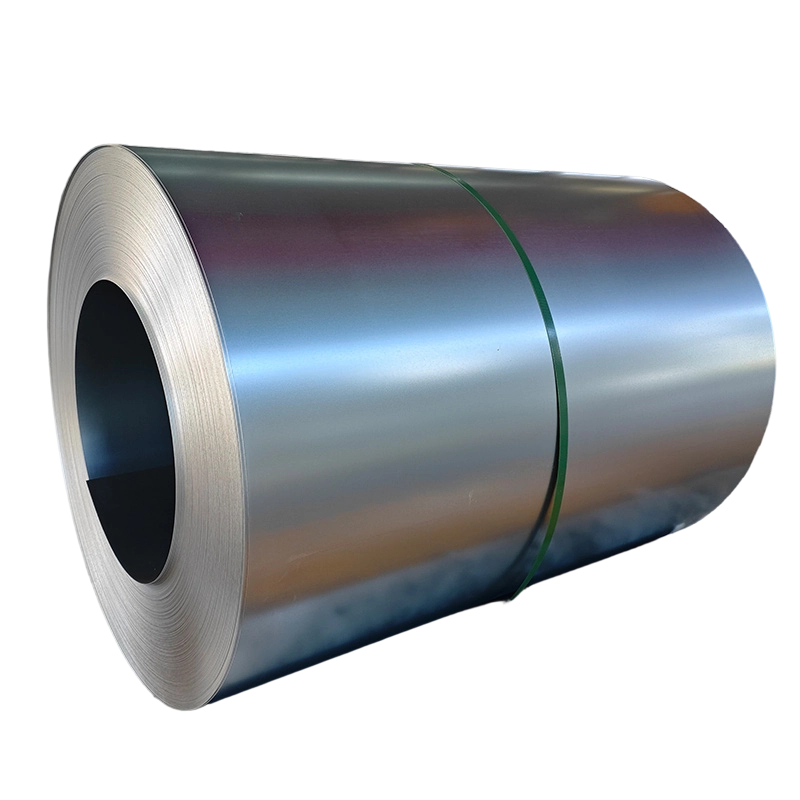

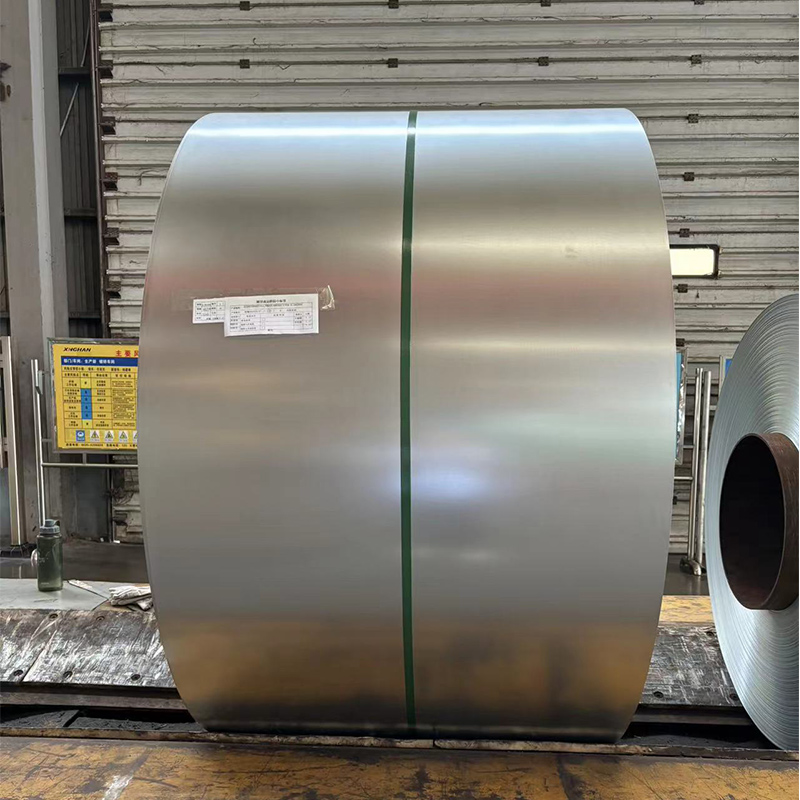

Zero Spangle Galvanized Steel Coil

Superior Surface Quality & Stability: The zero-spangle process eliminates color variation, zinc nodules, and zinc ash, ensuring a bright, uniform, and smooth surface ideal for applications requiring high appearance standards.

Enhanced Performance & Durability: Offers excellent corrosion resistance, weldability, cleanability, and high mechanical strength, supporting deep stamping, bending, and long-term outdoor or industrial use.

Advanced Production Technology: Equipped with intelligent visualization control, L-shaped annealing furnace, high-performance air knives, and full Siemens automation, delivering high efficiency, energy savings, and stable product quality.

Wide Adaptability for High-End Applications: Suitable for color-coated substrates, home appliances, automotive structural/interior panels, electrical cabinets, architectural decoration, and furniture—meeting stringent requirements for both aesthetics and durability.

Product Overview

Zero spangle galvanized steel coil is produced using mild, ultra-low carbon steels and structural steels, covering a thickness range of 0.3–2.0 mm and a width range of 700–1300 mm. It offers excellent corrosion resistance, good formability, and consistent surface quality, making it suitable for a wide range of construction and industrial applications.

Xinghan’s zero spangle galvanized products feature significantly improved weldability, corrosion resistance, cleanability, and appearance quality. Advanced production processes completely eliminate common surface defects such as color variation, zinc nodules, and zinc ash, ensuring a uniform, bright, and smooth finish.

The material delivers high strength, durability, and excellent stamping performance, meeting the demands of applications requiring strict appearance and long-term performance. It is widely used in high-corrosion-resistant color-coated substrates, home appliances (e.g., housings and back panels), and automotive components (e.g., structural parts, interior/exterior panels). It is also an ideal choice for electrical cabinets, architectural decoration, and furniture manufacturing, where both aesthetics and reliability are essential.

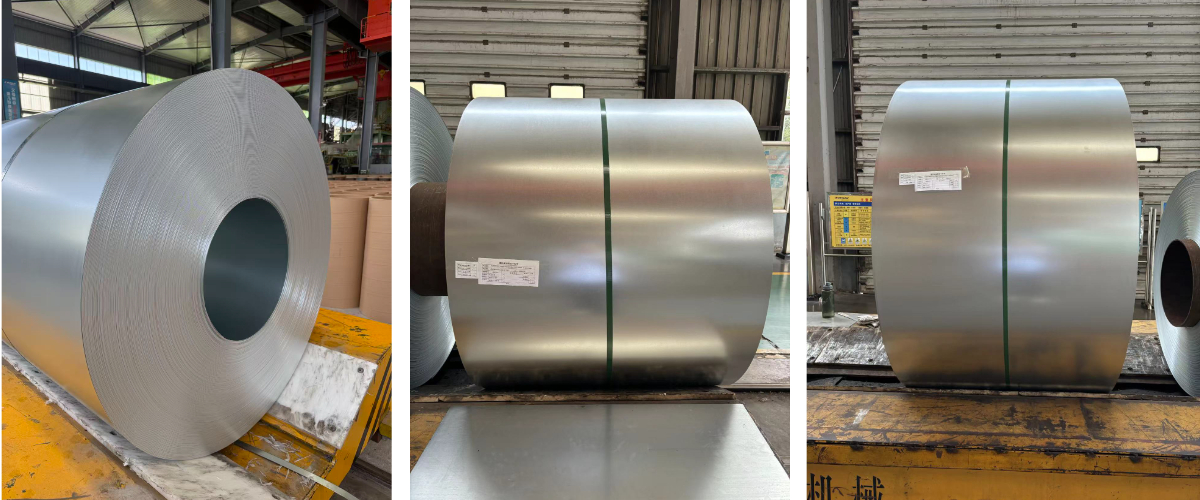

Galvanized production line with zero spangle

Xinghan's zero spangle production line adopts a fully intelligent visualization control system, integrating zinc ash humidification and automatic filtration, and enabling real-time monitoring of the zinc bath level. The line is equipped with core equipment, including an advanced L-shaped annealing furnace, high-speed mobile air cooling equipment, high-performance air knives, skin-pass mills, tension levelers, online thickness gauges, and plate temperature gauges, etc. The entire line operates automatically by using the Siemens control system, featuring significant advantages such as high efficiency, environmental protection, energy saving, and high automation level. The overall configuration of this production line reaches the domestic leading level, thereby effectively ensuring the excellent quality of zero spangle galvanized sheet.

Available range and production capacity

Production Line | Speed (m/min) | Thickness (mm) | Width (mm) | Zinc Coating (GSM) | Surface Treatment | Annual Capacity (MT) |

Zero Spangle Galvanizing Line | 200 | 0.3–2.0 | 700–1300 | ≥40 | Chromated, AFP, Oiled | 350,000 |