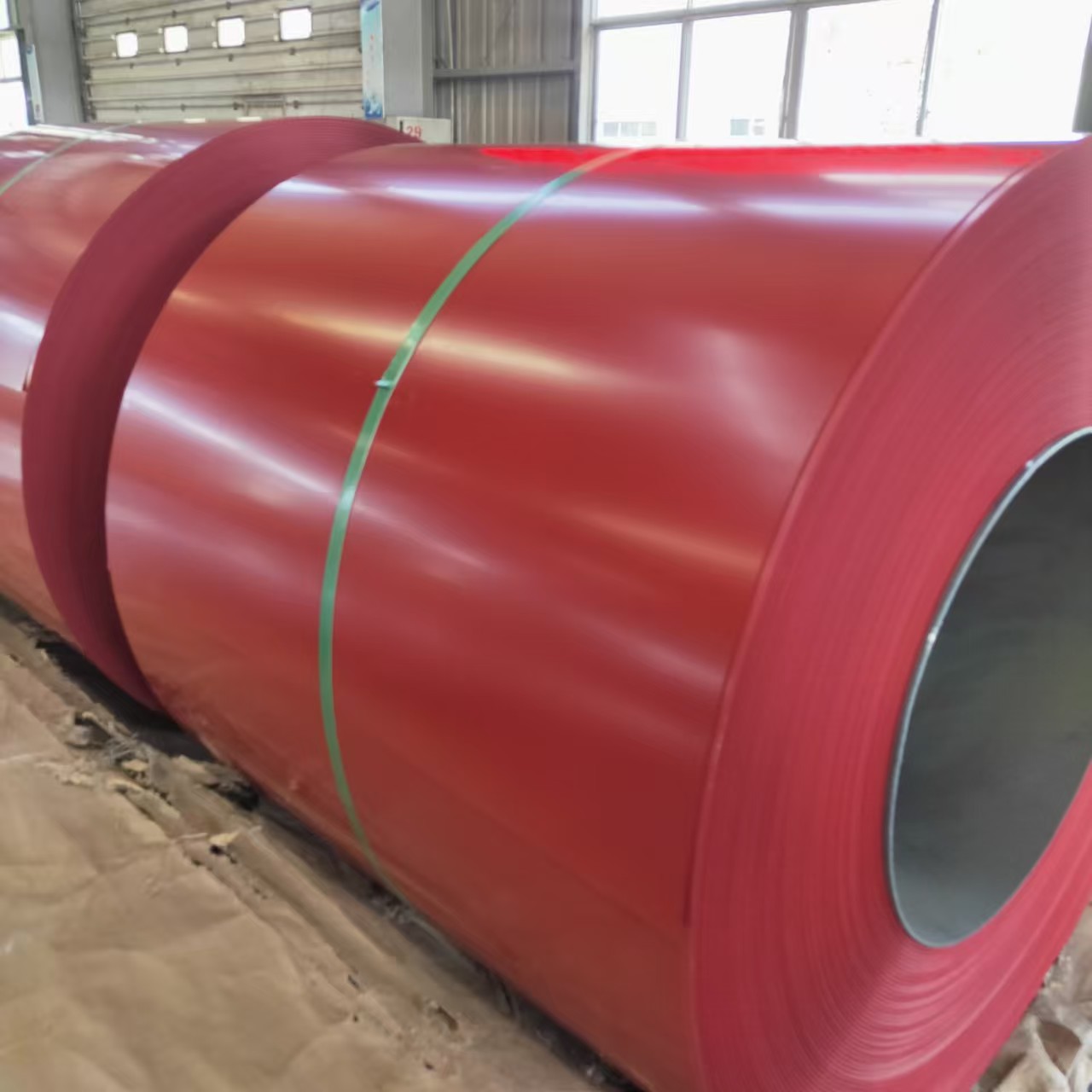

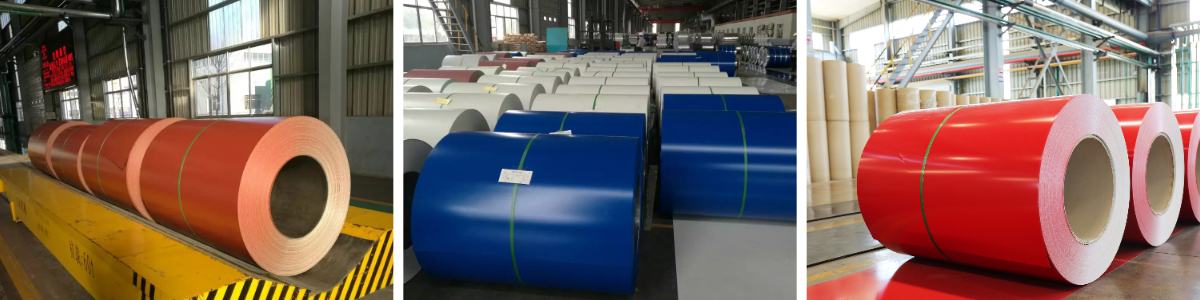

Prepainted Steel Coil

Excellent Corrosion & Weather Resistance: Multiple coating systems (PE, HDP, SMP, PVDF, PU, etc.) provide long-lasting durability from 10–30 years.

Wide Application Range: Suitable for construction, public buildings, chemical plants, mining, food/pharma cleanrooms, electronics, animal husbandry, and more.

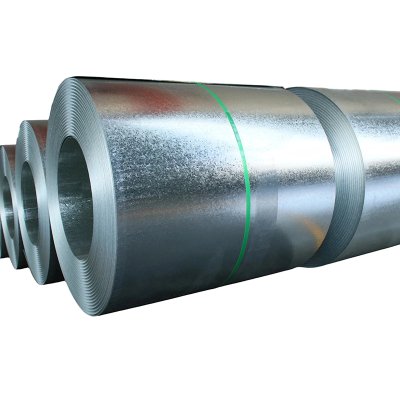

High-Quality Substrate Protection: Uses galvanized, galvalume, or ZAM substrates with high zinc coating and thick top coats for strong resistance to acid, alkali, humidity, and abrasion.

Versatile Functional Options: Offers antibacterial, anti-static, easy-clean, high-strength, and high-corrosion-resistant coatings to meet diverse industry needs.

Prepainted steel sheet is also referred to as "color coated plate" or "color plate". It is usually based on the galvanized steel sheet and galvalume steel sheet for surface treatment, on its surface coated with a certain thickness of paint or adhesion on a layer of organic film, after curing molding to become "color plate", with excellent corrosion resistance, formability, decorative. It is widely used in construction, home appliances, light industry, transportation and other industries, and has become an ideal composite material.

Coating Types

Coating Type | Recommended Substrate Type | Coating Thickness (μm) | MEK | T-Bend | 5% HCl | 5% NaOH | Neutral Salt Spray | QUV-A | Environmental Aging Performance |

Polyester (PE) | Z/AZ/ZM | ≥20 | ≥200 times | 3T | 24 hours | 24 hours | 1000 hours | 1000 hours | 10 years |

High Durability Polyester (HDP) | Z/AZ/ZM | ≥23 | ≥200 times | 3T | 24 hours | 24 hours | 1500 hours | 1500 hours | 15 years |

Silicone Modified Polyester (SMP) | Z/AZ/ZM | ≥23 | ≥200 times | 3T | 24 hours | 24 hours | 1500 hours | 1500 hours | 15 years |

Polyvinylidene Fluoride (PVDF) | Z/AZ/ZM | ≥25 | ≥300 times | 2T | 24 hours | 24 hours | 2000 hours | 3000 hours | 20-30 years |

Polyurethane (PU) | Z/AZ/ZM | ≥40 | ≥100 times | 2T | 24 hours | 24 hours | 720 hours | 1000 hours | 10-20 years |

Cold Laminated Film | Z/AZ/ZM | ≥100 | / | 0T | 360 hours | / | / | / | 10 years |

Color Printed | Z/AZ/ZM | ≥25 | ≥100 times | 3T | 24 hours | 24 hours | 600 hours | 1000 hours | 10 years |

Texture, Suede | Z/AZ/ZM | ≥25 | ≥100 times | 2T | 24 hours | 24 hours | 1000 hours | 1000 hours | 10 years |

High Corrosion Resistant Polyester (PE.PRO) | Z/AZ/ZM | ≥25 | ≥1000 times | 3T | 120 hours | 120 hours | 2000 hours | 2000 hours | 15 years |

High Corrosion & Weather Resistant Polyester (HDP.PRO) | Z/AZ/ZM | ≥25 | ≥1000 times | 3T | 120 hours | 120 hours | 2500 hours | 3000 hours | 20 years |

Color Coated Sheet Selection Guide

Public Buildings

◎ Application Industries

Airports, stadiums, railway stations, exhibition centers, science and technology museums, etc.

◎ Industry Characteristics

Public buildings attract significant public attention, making aesthetics and durability the primary considerations for color coated steel sheets. Requirements for coating color retention, chalk resistance, and a complete, fine surface are particularly important.

◎ Selection Recommendation

It is recommended to use substrates such as AZ150 galvalume sheet or Z275 galvanized sheet and above. The top coat generally uses PVDF fluorocarbon or HDP high durability polyester, with color schemes mostly based on light colors.

Metallurgy & Power Industry

◎ Industry Characteristics

Non-ferrous metal smelting plants (copper, zinc, aluminum, lead, etc.) present the most challenging environments for the service life of color coated sheets. Steel plants and power plants also produce corrosive media, demanding high corrosion resistance from the color coated sheets.

◎ Selection Recommendation

Given the specific characteristics of the metallurgy and power industries, it is generally recommended to select PVDF fluorocarbon, SDP super high durability, or HDP high durability color coated sheets.

Chemical Industry

◎ Industry Characteristics

Chemical products are volatile and can easily produce acidic or alkaline volatile substances with significant corrosiveness. When these condense with moisture, they form droplets on the sheet surface, corroding the coating and potentially progressing to the zinc layer or even the steel substrate.

◎ Selection Recommendation

Considering the specific corrosion resistance requirements of the chemical industry, it is recommended to use PVDF fluorocarbon, SDP super high durability, or HDP high durability color coated sheets. The substrate should be Z275 galvanized steel or AZ150 galvalume, with a top coat thickness of 20-25 µm.

Corrosion Resistance Comparison: PVDF Fluorocarbon > SDP Super High Durability > HDP High Durability

Cost Comparison: PVDF Fluorocarbon > SDP Super High Durability > HDP High Durability

Mining, Cement, & Aggregate Industry

◎ Industry Characteristics

Mining sites have harsh environments with severe dust, often containing metal particles. When settled on the sheet surface and soaked by rain, this dust can cause rust stains, leading to significant corrosive damage. Aggregate settled on the surface, when moved by wind, also causes substantial abrasion to the coating. For enclosed plants in the cement and aggregate industries, the corrosion resistance requirements for the interior color coated panels are also high.

◎ Selection Recommendation

It is recommended to select SMP silicone modified polyester sheets for their corrosion, scratch, and abrasion resistance. The substrate should be galvanized steel with a double-side zinc coating ≥120 g/m², and the top coat thickness should be ≥20 µm.

Food and Pharmaceutical Industry

◎ Application Industries

Areas with stringent antimicrobial requirements, such as clean production workshops for food and pharmaceuticals, and hospitals.

◎ Industry Characteristics

The food and pharmaceutical industries are subject to special national regulations, with extremely strict hygiene standards for production environments. Non-compliant hygiene conditions can directly impact the safety of food and pharmaceutical products.

◎ Selection Recommendation

In the food and pharmaceutical industries, antibacterial color coated sheets and easy-clean color coated sheets are widely used due to their unique coatings.

Antibacterial color coated sheets utilize special enamel-based antibacterial agents, which are non-toxic and provide semi-permanent antibacterial effects along with far-infrared radiation. These sheets achieve a bacterial inhibition rate of over 99% against E. coli and Staphylococcus aureus.

Easy-clean color coated sheets feature a coating with excellent hydrophilicity, making the surface easy to clean.

To meet the stringent antimicrobial requirements in these industries, it is recommended to use antibacterial or easy-clean color coated sheets. For the substrate, galvanized steel with a double-side zinc coating ≥80 g/m² is recommended, and the top coat thickness should be ≥20 µm.

Metal Arched Roof Color Coated Sheet Selection Guide

◎ Application Industries

Primarily used in trading markets, exhibition halls, storage and logistics facilities, industrial plants, wholesale markets, small sports venues, aircraft hangars, etc.

◎ Industry Characteristics

A metal arched roof integrates the roof panel and truss into a unified structural system. This design is widely adopted due to its low cost, short construction period, excellent arch quality, aesthetic appeal, and efficient use of internal space. However, some arched roofs are constructed without beams or purlins and feature large spans, placing higher demands on the strength of the color coated sheets.

◎ Selection Recommendation

Depending on the span of the arched roof, it is recommended to use high-strength structural color coated sheets with a yield strength ranging from 280 MPa to 550 MPa. The corresponding material grades are: TS280GD+Z to TS550GD+Z.

The substrate should have a double-side coating mass of no less than 120 g/m², and the top coat thickness should be no less than 20 µm.

The type of coating can be selected based on the service environment and project budget. Options include PVDF fluorocarbon, TWPU enhanced polyester, HDP high durability polyester, or standard PE polyester.

Animal Husbandry Industry

◎ Industry Characteristics

The animal husbandry environment is characterized by high temperatures and high humidity, leading to the generation of significant ammonia gas on-site. When ammonia comes into contact with water, it forms an alkaline substance that is highly corrosive to barn structures. Additionally, the frequent use of strongly oxidizing cleaning and disinfectants can cause considerable corrosion to the interior color coated panels. The pH level in animal husbandry buildings typically ranges between 9 and 14, influenced by factors such as architectural design, ventilation, and cleaning practices.

◎ Selection Recommendation

For the animal husbandry industry, Xinghan Coating recommends the use of aluminum-zinc (AZ) or zinc-aluminum-magnesium (ZAM) substrates. The substrate should have a double-side zinc coating mass of no less than 100 g/m², with a top coat thickness ≥45 µm and a back coat thickness ≥45 µm.

Employing highly corrosion-resistant substrates and specialized acid-alkali resistant coatings can mitigate corrosion caused by ammonia, hydrogen sulfide, microorganisms, and disinfectants on the color coated sheets. This approach helps extend the service life of livestock buildings and reduce long-term maintenance and renovation costs.

Selection Guide for Color Coated Panels in Textile/Electronic Workshops

◎ Application Industries

Industries with high requirements for anti-static protection, such as apparel, textiles, electronics, instrumentation, and medical facilities.

◎ Industry Characteristics

In textile and electronic workshops, static electricity poses significant risks, ranging from disruptions to normal production to serious safety incidents. Therefore, there is a high demand for effective anti-static measures.

◎ Selection Recommendation

Anti-static color coated panels are widely used in these industries due to the incorporation of special conductive pigments in the coating. These panels exhibit surface resistance, allowing static electricity to dissipate as electrical energy, thereby preventing dust accumulation and facilitating easy cleaning.

As a result, anti-static color coated panels are extensively applied in production environments requiring dust and static control, such as textiles, electronics, optical instruments, and medical facilities.

For substrate selection, it is recommended to use panels with a double-side zinc coating ≥80 g/m² and a top coat thickness ≥20 µm.