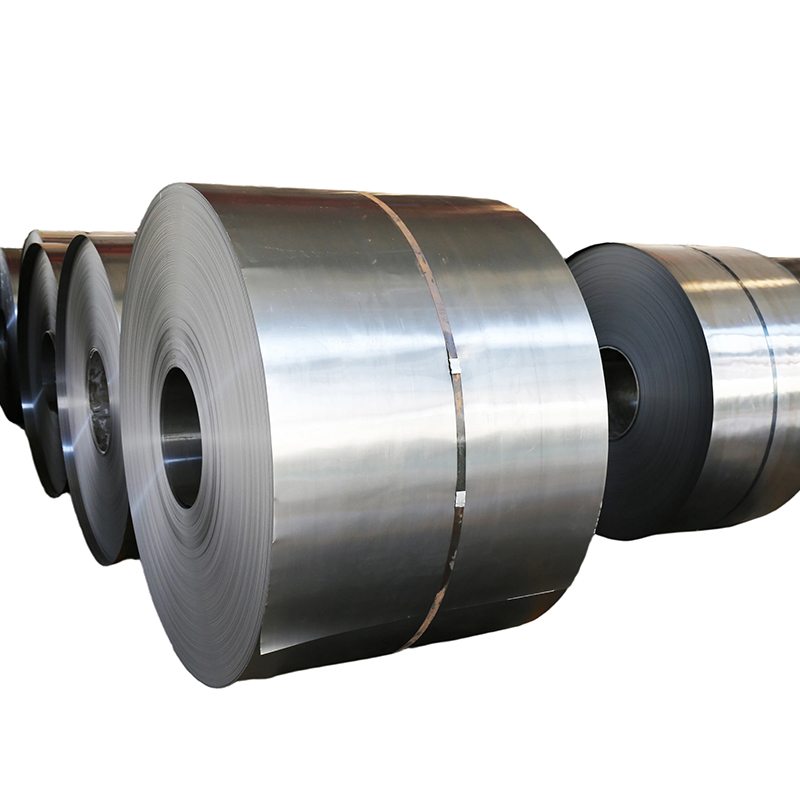

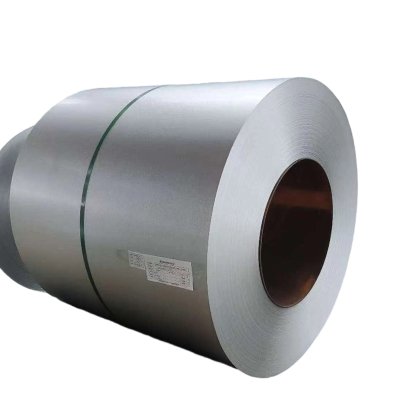

Cold Rolled Stainless Steel Coil

High Precision & Smooth Surface: Delivers uniform finish, accurate thickness, and excellent dimensional control.

Strong Performance & Corrosion Resistance: Offers high strength, good formability, and superior resistance to corrosion.

Large Capacity & Stable Quality: Seven advanced rolling lines with 1 million tons annual capacity ensure consistent, GB/T-compliant quality.

Reliable Testing & Quality Assurance: A well-equipped test center provides comprehensive testing to guarantee stable and reliable product performance.

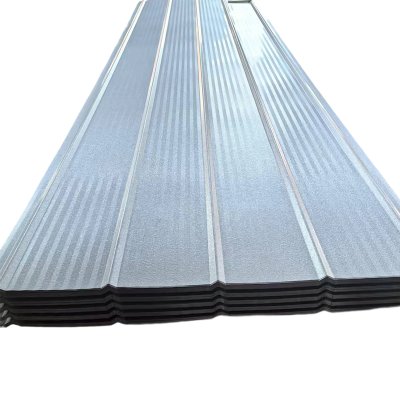

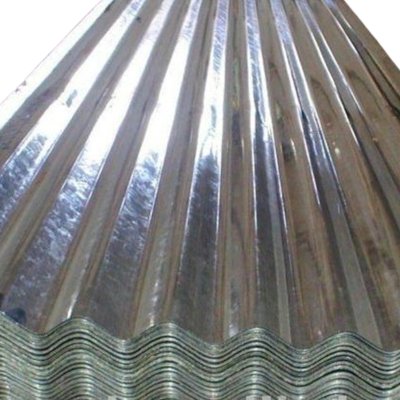

Cold rolled stainless steel coil is produced by processing stainless steel sheets through cold rolling, resulting in a smooth, uniform surface with precise thickness and excellent dimensional accuracy. This material offers superior corrosion resistance, high strength, and excellent formability, making it suitable for deep drawing, bending, and other complex fabrication processes. Economical and practical, it is widely used in construction, household appliances, automotive components, container manufacturing, mechanical and electrical equipment, and other industrial applications.

Coldroll lines

There are 7 single-machine reversible cold rolling units, adopting advanced cold rolling technology at home and abroad to ensure that the product quality is not lower than GB/T708-2019, GB/T710-2008. In order to ensure the production efficiency of the unit, the design of the single equipment in the unit is also based on the most advanced structure and the highest degree of automation in the current area at home and abroad. The company's rollings are divided into three types: 1150/950/1450, with an annual production capacity of 1 million tons.

Available range and production capacity

Production Line | Highest Speed (m/min) | Thickness (mm) | Width (mm) | Coil ID (mm) | Annual Capacity (MT) |

950 Rolling | 480 | 0.12 - 0.8 | 650 - 950 | 508 | 100,000 |

1150 Rolling | 1200 | 0.08 - 3.0 | 700 - 1050 | 508 | 300,000 |

1450 Rolling | 1200 | 0.18 - 3.0 | 750 - 1300 | 508 | 600,000 |

Test center

The test center experiment area covers an area of more than 1500 square meters, with technical experts and professional testing personnel 10 people. All the introduction of advanced professional testing equipment, industry ability of steel chemical composition analysis, mechanical property testing, microstructure analysis, performance test of surface and coatings, etc. can provide reliable guarantee for the quality of the products. At the same time, it can provide test support for product development and improvement. Another test center has pressure, thermal, length measurement calibration ability, can guarantee the accuracy of the monitoring instrument in production process, and stable product quality.

Product Application Cases

Qatar Hamad International Airport Phase B expansion project

Hamad International Airport, formerly known as the New Doha International Airport, is located in the Middle East, Qatar's capital city of Doha, an international airport. Hamad International Airport put into operation in 2014, is one of the most advanced facilities in the Middle East, the largest passenger throughput of the aviation hub. The Phase B expansion of the airport is under way, including the construction of 11,000 square metres of new retail and dining areas and a 10,000 square metre indoor garden, as well as a new cargo terminal with a capacity of 60 million passengers per year. Once completed, the airport's annual passenger capacity will increase to 70 million, with the Middle East expected to double by 2040, according to the latest International Air Transport Association data.