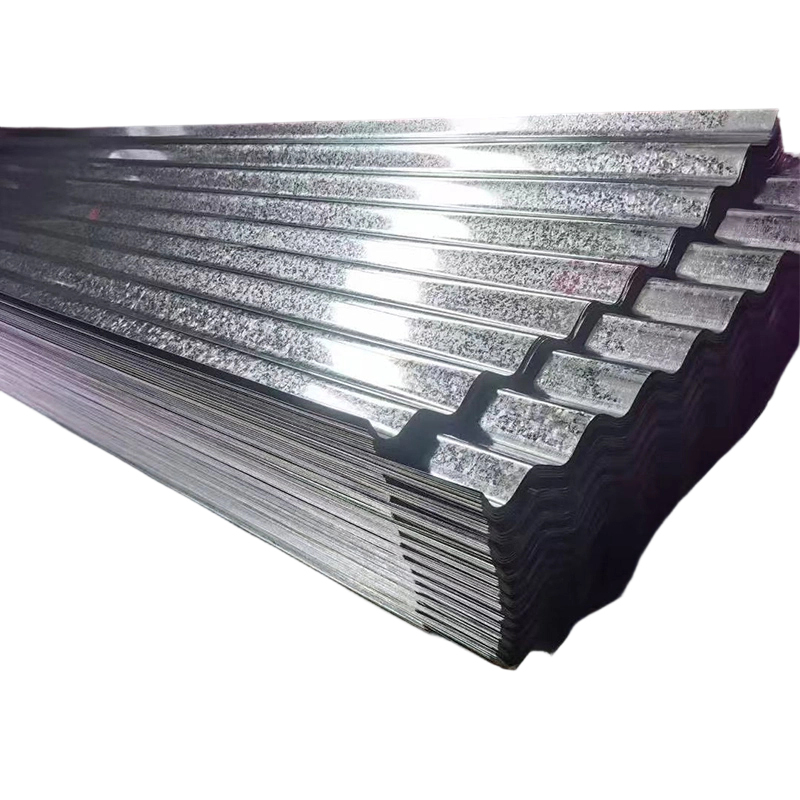

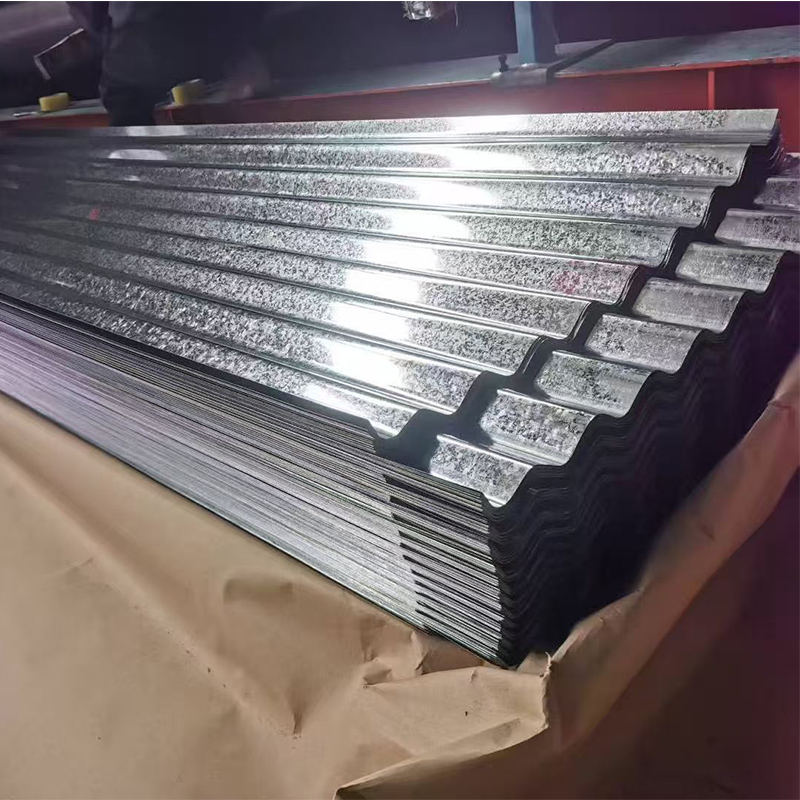

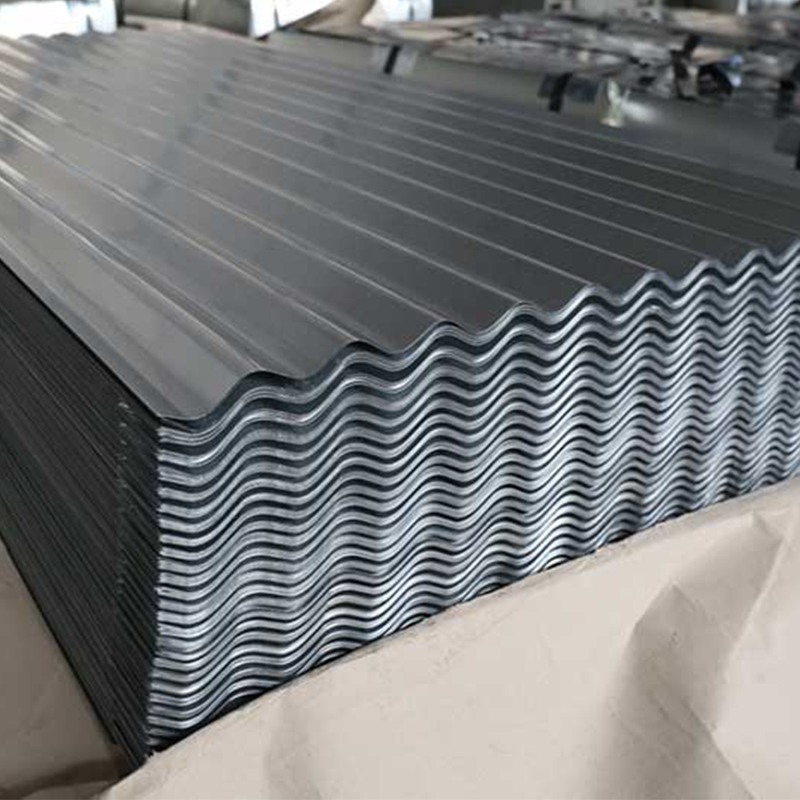

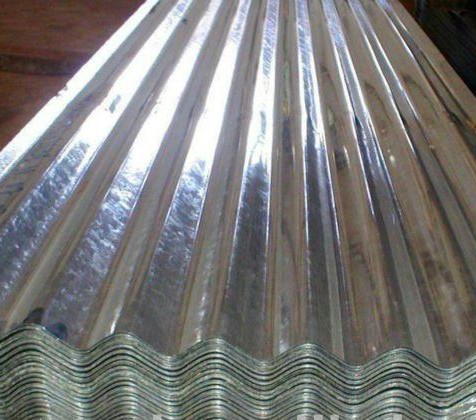

Corrugated Metal Sheets feature fully automated production with quick mold changes, one-button operation, low energy consumption, and precise CNC forming with minimal wear. The line uses a unique design, multi-functional hydroforming, and an intuitive control interface to ensure high density, high strength, and diverse product options. By switching molds, the system can produce various high-quality corrugated sheet profiles.

Corrugated Metal Sheets

High Corrosion Resistance and Durability: Engineered for long-term performance, the sheets withstand harsh environmental conditions, making them ideal for infrastructure, energy, and transportation projects requiring extended service life.

Excellent Formability and Precision: Fully automated production with CNC-controlled hydroforming ensures precise corrugation, consistent thickness, and minimal wear, supporting complex profiles and high-quality finishes.

Versatile Applications: Mold-change flexibility allows production of diverse sheet profiles, enabling use across airports, high-speed railways, environmental protection facilities, and specialized automotive structures.

Production Line Specifications

Production Line | Max. Process Speed (m/min) | Thickness (mm) | Width (mm) | Length (mm) | Sets | Annual Capacity (MT) |

Corrugation | 100 | 0.1 - 0.5 | 650 - 1250 | 500 - 6000 | 8 | 70,000 |

Product Packaging

About Us

Xinghan Coating is a premium coating brand under Guanxian Renze Composite Materials Co., Ltd., specializing in high-corrosion-resistant, ultra-durable, and easy-forming coated steel products. With over two decades of experience in coated sheet manufacturing, Xinghan Coating consistently follows a development path centered on high standards, high quality, and high efficiency. Its galvanized, galvalume, and pre-painted steel sheets have earned strong recognition in both domestic and international markets, supported by comprehensive solutions that cover testing, application, and installation.

The company operates on a 400,000-square-meter site and employs more than 1,200 staff members. It runs 18 major production lines with an annual output capacity of 2 million tons of pickled and cold-rolled products and 1.7 million tons of coated materials. Xinghan maintains close partnerships with leading universities, holding over 50 invention and utility model patents. Its CMA-certified quality inspection center strengthens product reliability and process control.

With superior product performance and responsive after-sales service, the company has established long-term strategic cooperation with more than 1,000 domestic and overseas enterprises. Its products are distributed across over 20 provinces in China and exported to more than 100 global markets including the EU, Africa, the Americas, Southeast Asia, and Central Asia, earning widespread trust and a solid brand reputation.

Application Scenarios

Based on successful use across multiple flagship global projects, this product is well-suited for engineering fields that require high corrosion resistance, strength, durability, and excellent surface quality. Key application areas include:

1. Large-Scale Public Infrastructure

Representative project: Qatar Hamad International Airport Phase B Expansion.

The product is applied in airport terminals, commercial areas, and supporting facilities where long service life, superior corrosion resistance, and high-quality surfaces are essential.

2. Rail Transit and High-Speed Railway Construction

Representative project: Jakarta–Bandung High-Speed Rail (Indonesia).

Used in structural components that demand high strength, reliability, and the ability to withstand diverse environmental conditions, ensuring long-term stable operation of major rail systems.

3. Energy and Environmental Protection Projects

Representative project: Ningxia National Energy Group Coal Yard Closure Project.

Applied in environmental enclosure structures, dust-control systems, and energy facilities that require strong weather resistance, structural stability, and excellent anti-corrosion performance to support large-scale environmental improvement efforts.

4. Automotive Manufacturing and Special-Purpose Vehicles

Representative project: Hubei Yizhuan Automobile Cold Chain Vehicle Assembly Line.

Used in cold-chain compartments, aluminum tank bodies, and special vehicle structural parts that require superior formability, smooth surface quality, and strong corrosion protection to meet the standards of high-end vehicle manufacturing.