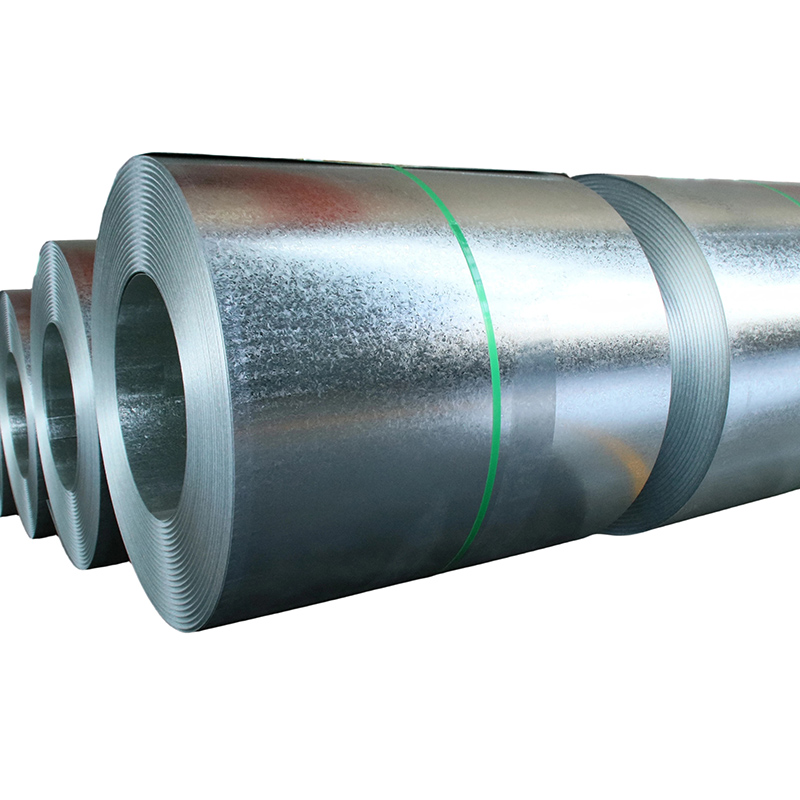

Regular Spangle Galvanized Steel

Outstanding Corrosion Resistance: The zinc coating provides long-lasting protection against rust and environmental damage, greatly extending the service life of the steel.

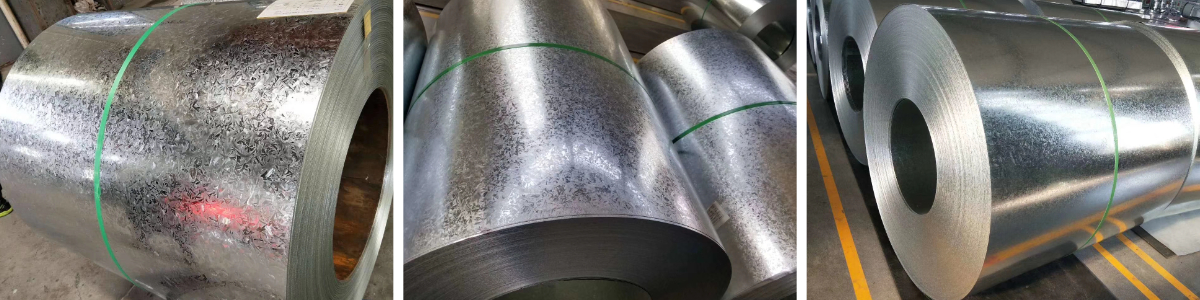

Excellent Surface Quality & Processability: Smooth surface finish allows for painting, welding, stamping, bending, and deep drawing, making it suitable for complex manufacturing needs.

High Strength with Lightweight Design: Structural grades offer thinner thickness and lighter weight without compromising strength, reducing material usage and overall cost.

Wide Range of Applications: Versatile material widely used in construction, steel structures, household appliances, automotive, shipbuilding, container production, and mechanical & electrical industries.

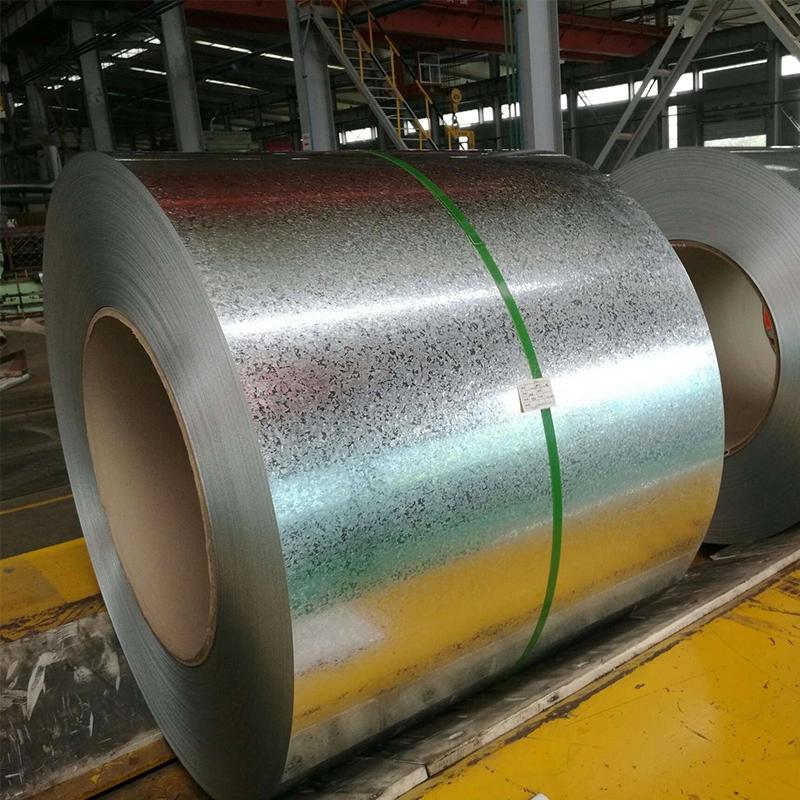

Galvanized steel, a coiled cold-rolled steel plate is continuously dipped in a plating tank with molten zinc, and a layer of zinc is fused on the surface of the anticorrosion material.

It is a steel based composite material, which can effectively prevent the corrosion of steel, prolong the service life, has excellent corrosion resistance, good surface quality, is conducive to deep processing, economical and practical, and is widely used in construction, household appliances, vehicles and ships, container manufacturing, Mechanical and electrical industries and other fields.

Our galvanized steel coil is produced by continuously dipping cold-rolled steel plate into a plating bath with molten zinc, fusing a uniform zinc layer onto the steel surface. This process forms a durable steel-based composite material with superior corrosion resistance and long service life.

Available Grades & Dimensions:

Type of products | material | Thickness (mm) | Width (mm) | Uses and characteristics |

Mild and ultra-low carbon steels | SGCC.DX51D. DX52D | 0.1-3.0 | 700-1300 | Construction and general household |

DX53D | 0.3-1.0 | 700-1300 | For deep drawing applications.It has greater ductility than the deep drawing grade and is suitable for manufacturing parts with extremely deep drawing and more complex processing. | |

Structural Steel

| S220GD+Z. SS33. SGC340 S250GD+Z. SS37. SGC400 S280GD+Z. SS40. SGC440 S300GD+Z S320GD+Z S350GD+Z. SS50. SGC490 S390GD+Z S420GD+Z S450GD+Z S550GD+Z. SS80 | 0.4-3.0 | 700-1300 | These products has excellent corrosion resistance and processing properties. It has a thinner thickness, lighter components, and more economical cost under the same strength.It is mainly used in the construction field, especially in steel structure buildings |

Features

Excellent Corrosion Resistance: The zinc coating effectively protects the steel substrate from rust and environmental damage.

High Surface Quality: Smooth and uniform coating suitable for secondary processing like painting, welding, and forming.

Strong Processing Performance: Ideal for cutting, stamping, bending, and deep drawing without compromising surface integrity.

Economical & Practical: Lightweight with thinner sections while maintaining high strength, reducing cost and material usage.

Structure

Galvanized steel coil is composed of a cold-rolled steel base coated with a continuous layer of molten zinc. The metallurgical bond between zinc and steel provides both physical strength and chemical protection. This structure makes galvanized coils suitable for demanding environments and long-term durability.

Applications

Galvanized steel coil is widely used across multiple industries due to its durability and versatility:

Construction Industry: Roofing sheets, wall panels, ceiling frames, purlins, and steel structures.

Household Appliances: Outer shells of refrigerators, washing machines, ovens, and ventilation systems.

Automotive & Transportation: Body panels, chassis components, shipping containers, and vehicle frames.

Mechanical & Electrical Industry: Electrical cabinets, lighting fixtures, ducts, and machinery housings.

Marine & Agricultural Use: Shipbuilding, grain silos, greenhouses, and fencing solutions.