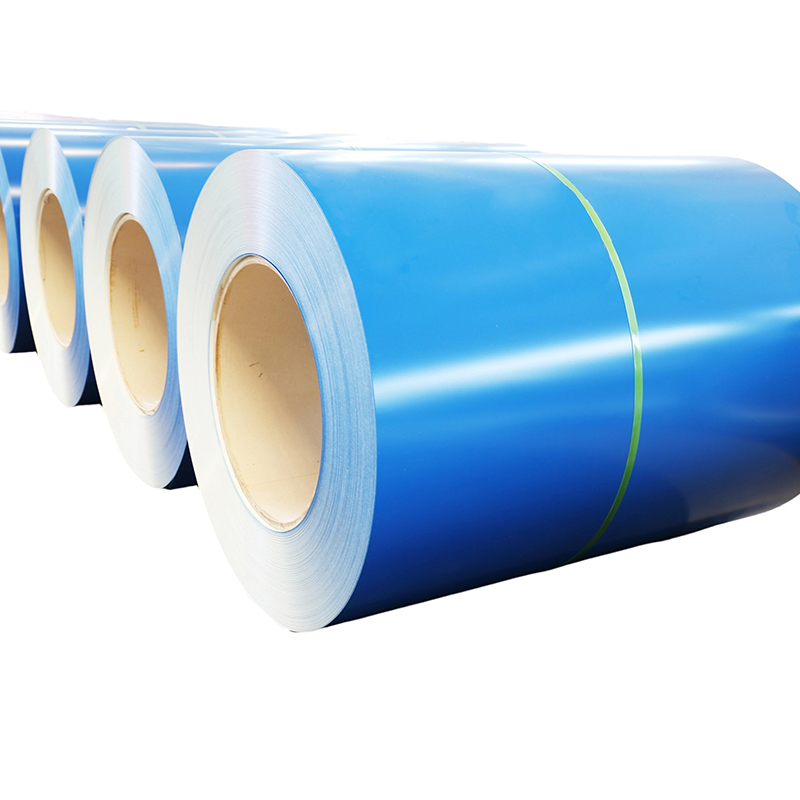

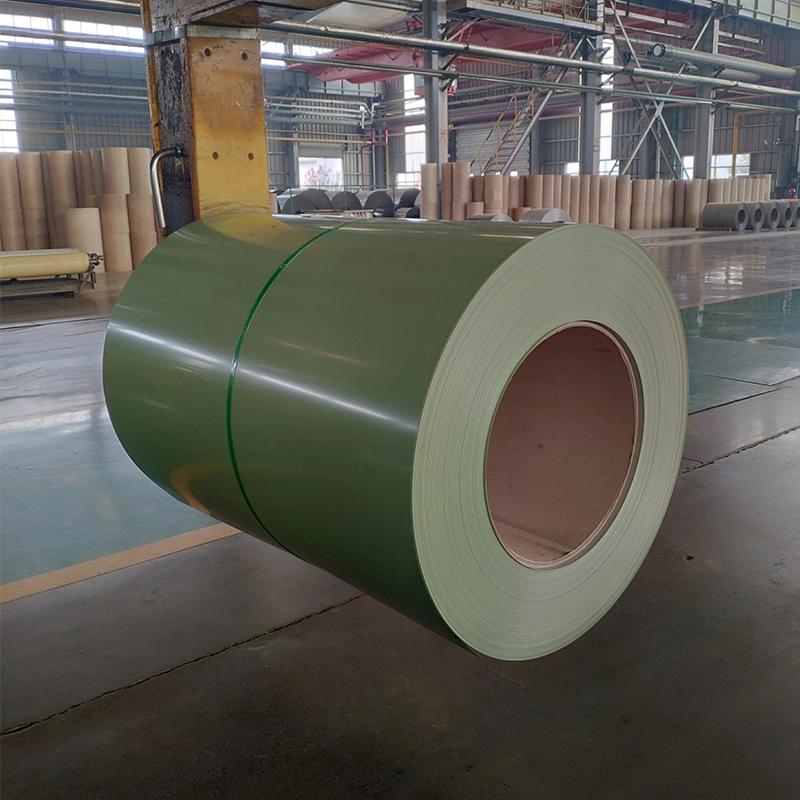

Prepainted Galvalume Steel

Long-Lasting Protection: Service life of 10–30 years depending on coating system, even in harsh environments.

Versatile Coating Options: Wide range of paints (PE, HDP, SMP, PVDF, PU, etc.) for customized performance and aesthetics.

Excellent Workability: Maintains high strength and ductility for bending, stamping, and deep drawing applications.

Wide Application Range: Ideal for construction, appliances, transportation, and decorative industries, meeting both functional and aesthetic requirements.

Prepainted steel coil, also known as “color coated steel” or simply “color coil,” is typically produced by applying surface treatments to galvanized or galvalume steel sheets. A layer of paint or an organic coating of specific thickness is applied to the surface and cured to form the finished color-coated sheet. This material combines excellent corrosion resistance, strong formability, and decorative appeal, making it widely used in construction, home appliances, light industry, transportation, and other sectors. It has become a preferred composite material for applications requiring durability and aesthetic quality.

Performance Parameter

Paint Type | type | Coating thickness um | MEK | Special bend | 5% HCI | 5% NaOH | Neutral salt spray | QUV-A | Ambient aging performance |

PE | Z/AZ/ZM | ≥20 | ≥200 | 3T | 24 hours | 24 hours | 1000 hours | 1000 hours | 10 years |

HDP | Z/AZ/ZM | ≥23 | ≥200 | 3T | 24 hours | 24 hours | 1500 hours | 1500 hours | 15 years |

SMP | Z/AZ/ZM | ≥23 | ≥200 | 3T | 24 hours | 24 hours | 1500 hours | 1500 hours | 15 years |

PVDF | Z/AZ/ZM | ≥25 | ≥300 | 2T | 24 hours | 24 hours | 2000 hours | 3000 hours | 20-30 years |

PU | Z/AZ/ZM | ≥40 | ≥100 | 2T | 24 hours | 24 hours | 720 hours | 1000 hours | 10-20 years |

Cold film | Z/AZ/ZM | ≥100 | / | 0T | 360 hours | / | / | / | 10 years |

Colorful printing | Z/AZ/ZM | ≥25 | ≥100 | 3T | 24 hours | 24 hours | 600 hours | 1000 hours | 10 years |

Textured Pattern | Z/AZ/ZM | ≥25 | ≥100 | 2T | 24 hours | 24 hours | 1000 hours | 1000 hours | 10 years |

PE.PRO | Z/AZ/ZM | ≥25 | ≥1000 | 3T | 120 hours | 120 hours | 2000 hours | 2000 hours | 15 years |

HDP.PRO | Z/AZ/ZM | ≥25 | ≥1000 | 3T | 120 hours | 120 hours | 2500 hours | 3000 hours | 20 years |

Features

Excellent Corrosion Resistance: Advanced paint systems provide long-lasting protection against rust, acid, alkali, and salt spray environments.

Superior Decorative Effect: Smooth, colorful, and customizable finishes including gloss, matte, embossed, and suede textures.

High Formability & Processing: Coated steel maintains strong bending, stamping, and deep drawing properties without cracking or peeling.

Durable Performance: UV resistance, aging stability, and service life up to 30 years depending on the coating system.

Digital Empowerment of the Full Prepainted Steel Production Process

Xinghan Coating operates an integrated production chain covering pickling, rolling, galvanizing, and coating, with an annual production capacity of 3.7 million tons. The company has implemented digital transformation and achieved CMM certification. By integrating ERP, MES, and EPOS systems, it connects all stages of the prepainted steel production process—from energy management to sales, manufacturing, and delivery—enabling product traceability and meeting customized customer requirements.

The facility has two prepainted steel production lines, primarily producing mid-to-high-end construction panels and appliance color-coated sheets. The lines were developed by well-known domestic design institutes. All transmission and power equipment in the production process are highly automated, allowing precise control throughout production. To ensure excellent paint adhesion and surface quality, multi-stage washing systems are used, significantly enhancing the finish of the coated sheets. The production lines are connected to curing ovens and equipped with high-efficiency, energy-saving fresh air systems and waste heat recovery systems, maximizing energy utilization and minimizing environmental impact.

Xinghan Coating has also introduced advanced prepainted steel production equipment using a double-coating, double-curing process, with an annual design capacity of 300,000 tons.

Production Line | Process | Substrate Type | Process Speed | Thickness (mm) | Width (mm) | Coil ID (mm) | Design Capacity (MT) |

Prepainted Steel Line | Double-coating & Double-curing | GI, GL, ZAM | 120 m/min | 0.12 – 1.0 | 650 – 1250 | 508 / 610 | 300,000 |

Quality Commitment

Xinghan Coating has obtained GB/T19001-2016 and ISO9001:2015 quality certifications and has established a comprehensive quality assurance system. Under this complete quality management framework, all stages—from order placement, order processing, product design, raw material procurement, production planning, manufacturing, quality control, testing and inspection, to product packaging, warehousing, and delivery—follow detailed procedures. The integrated production and sales computer management system further enhances operational efficiency and ensures consistent product quality.

Quality Inspection

Xinghan Coating’s prepainted steel lines are equipped with numerous advanced online testing instruments to ensure and improve product quality. The company has a complete set of equipment and methods for performance testing, allowing routine monitoring and control of all relevant properties of the produced prepainted steel sheets. This ensures that the products maintain a quality level that is among the leading standards domestically.