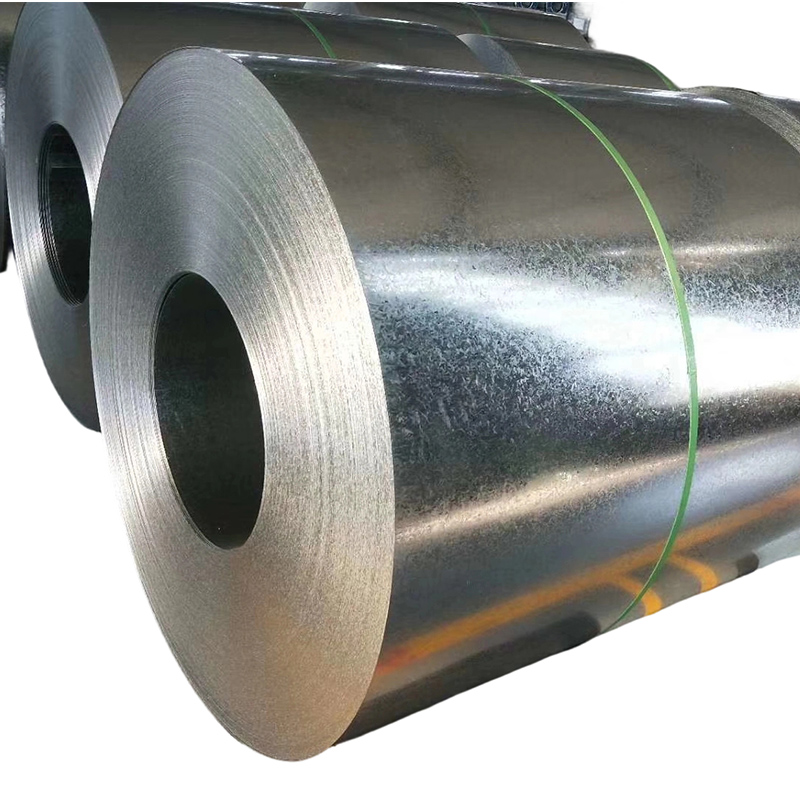

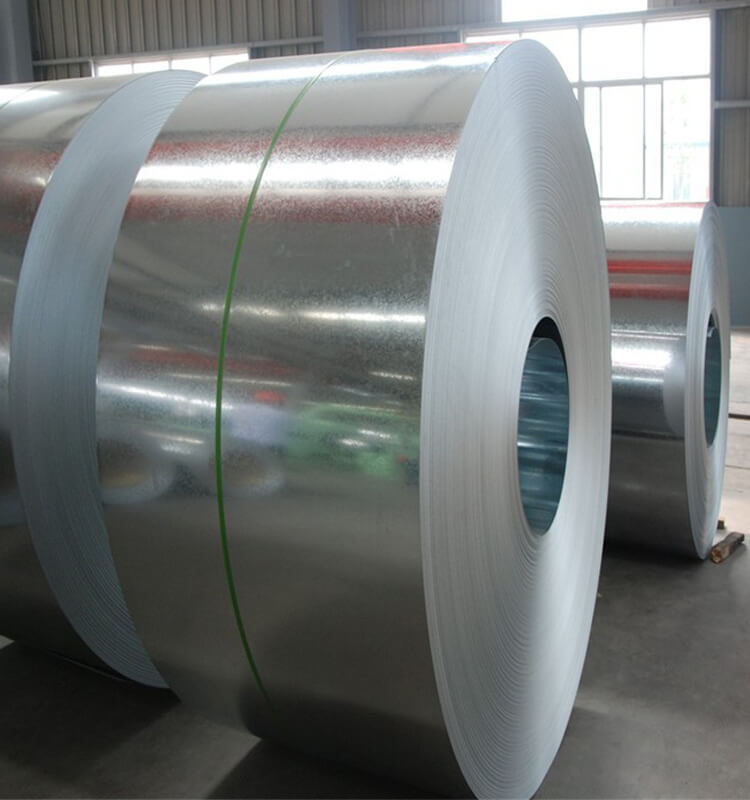

Large Spangle Galvanized Sheet

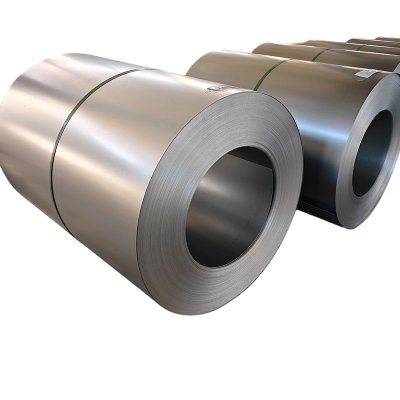

Superior Corrosion Protection: Hot-dip zinc coating forms a durable protective layer that prevents rust, greatly extends service life, and maintains reliability in harsh environments.

High Strength with Excellent Processability: Combines strong mechanical performance with good ductility, bendability, and formability—ideal for deep drawing, stamping, cutting, and complex fabrication.

Stable Quality Backed by Advanced Testing: Equipped with a 1,500+ m² testing center, professional technical team, and full sets of chemical, mechanical, microstructure, surface, and coating tests to ensure consistent product quality.

Economical & Widely Applicable: Cost-effective steel-based composite material widely used in construction, appliances, automotive parts, containers, and mechanical & electrical industries.

Galvanized steel is a coiled cold-rolled steel plate that is continuously dipped in a plating tank with molten zinc, fusing a layer of zinc onto the surface as an anti-corrosion material.

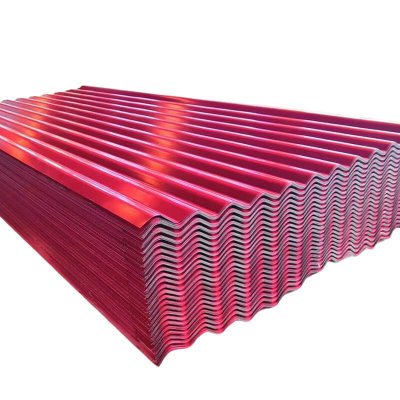

As a steel-based composite material, it can effectively prevent steel corrosion and prolong service life. It features excellent corrosion resistance, good surface quality, and is conducive to deep processing. Economical and practical, it is widely used in construction, household appliances, vehicles and ships, container manufacturing, mechanical and electrical industries, and other fields.

Performance Parameter

Type of Products | Grade/Material | Thickness (mm) | Width (mm) | Uses and Characteristics |

Mild and Ultra-Low Carbon Steels | SGCC, DX51D, DX52D | 0.1 - 3.0 | 700 - 1300 | Construction steel and general appliance steel. |

Mild and ultra-low carbon steels | DX53D | 0.3-1.0 | 700-1300 | For deep drawing applications, offering greater ductility than deep drawing grades, suitable for manufacturing components requiring extra-deep stamping forming and more complex processing. |

Structural Steel | S220GD+Z、SS33、SGC340 | 0.3 - 1.0 | 700 - 1300 | Deep drawing grade. Offers greater ductility than deep drawing grades, suitable for manufacturing components requiring extra-deep drawing and more complex processing. |

Testing Center

Test center experiment area covers an area of more than 1500 square meters, with technical experts and professional testing personnel 10 people. All the introduction of advanced professional testing equipment, industry ability of steel chemical composition analysis, mechanical property testing, microstructure analysis, performance test of surface and coatings, etc. can provide reliable guarantee for the quality of the products. At the same time, it can provide test support for product development and improvement. Another test center has pressure, thermal, length measurement calibration ability, can guarantee the accuracy of the monitoring instrument in production process, and stable product quality.