Prepainted Galvanized Steel Coil

High Durability: Advanced coating systems (PE/HDP/SMP/PVDF) deliver strong corrosion and weather resistance with a long service life.

Digitalized Quality Control: Full-process ERP + MES + EPOS integration ensures stable quality, high precision, and complete product traceability.

Superior Surface & Processing Performance: Automated lines with multi-stage rinsing and double-coat double-bake technology ensure excellent adhesion, smooth finish, and easy forming.

Proven Outdoor Reliability: Natural exposure testing with partners like KCC verifies long-term color retention and performance in harsh environments.

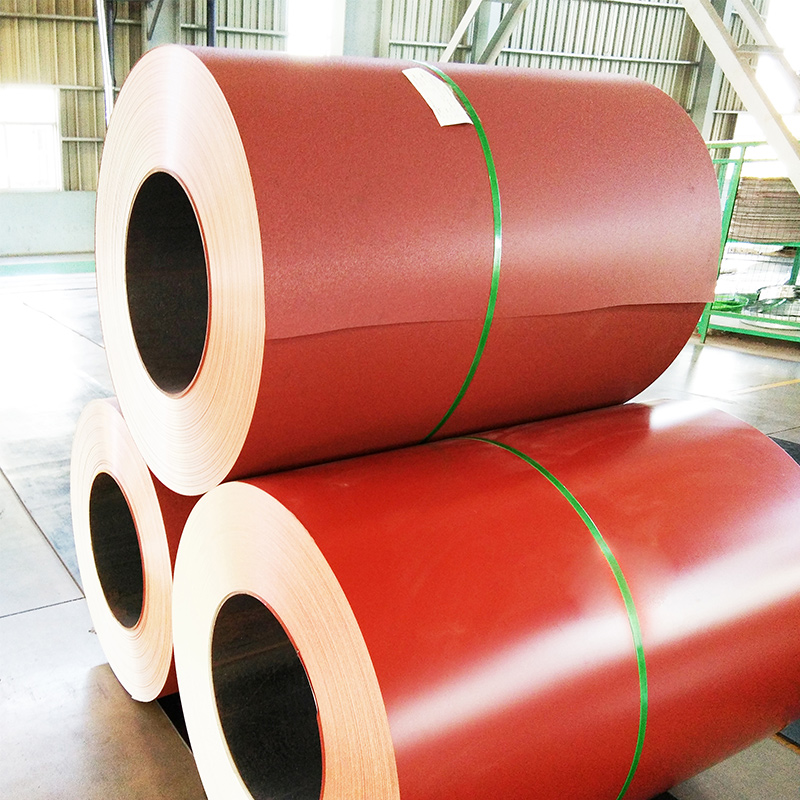

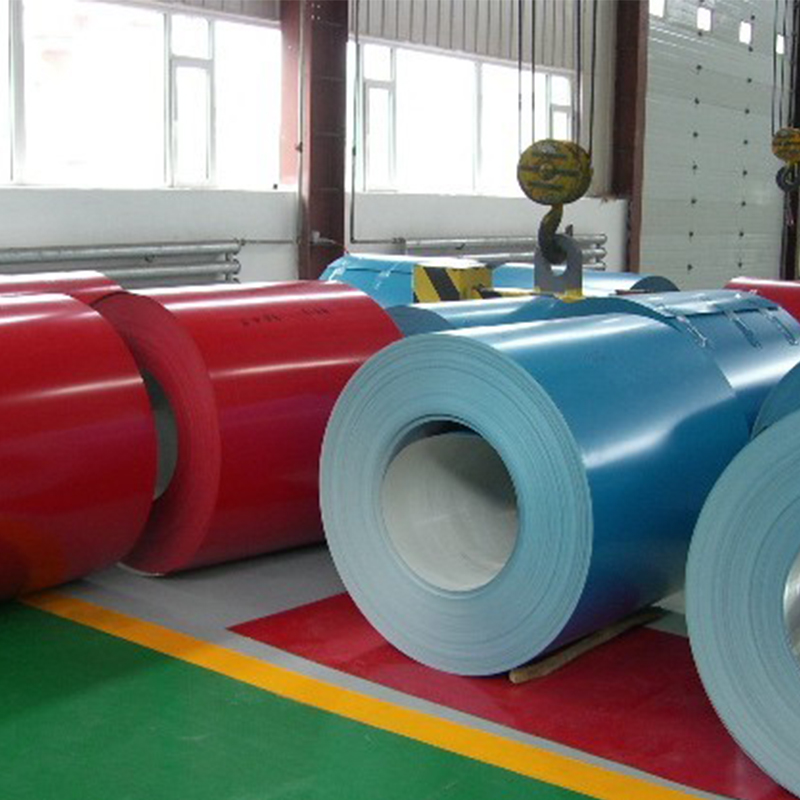

Prepainted steel sheet—commonly known as "color coated plate" or simply "color plate"—is produced by applying a layer of paint or organic film onto a galvanized or galvalume steel substrate. After coating and curing, it forms a finished panel with excellent corrosion resistance, good formability, and strong decorative appeal.

Thanks to its durability and versatility, it is widely used in construction, home appliances, light manufacturing, transportation, and other industries, making it a highly preferred composite material.

Coating Types

Coating Type | Recommended Substrate Type | Coating Thickness (μm) | MEK | T-Bend | 5% HCl | 5% NaOH | Neutral Salt Spray | QUV-A | Environmental Aging Performance |

Polyester (PE) | Z/AZ/ZM | ≥20 | ≥200 times | 3T | 24 hours | 24 hours | 1000 hours | 1000 hours | 10 years |

High Durability Polyester (HDP) | Z/AZ/ZM | ≥23 | ≥200 times | 3T | 24 hours | 24 hours | 1500 hours | 1500 hours | 15 years |

Silicone Modified Polyester (SMP) | Z/AZ/ZM | ≥23 | ≥200 times | 3T | 24 hours | 24 hours | 1500 hours | 1500 hours | 15 years |

Polyvinylidene Fluoride (PVDF) | Z/AZ/ZM | ≥25 | ≥300 times | 2T | 24 hours | 24 hours | 2000 hours | 3000 hours | 20-30 years |

Polyurethane (PU) | Z/AZ/ZM | ≥40 | ≥100 times | 2T | 24 hours | 24 hours | 720 hours | 1000 hours | 10-20 years |

Cold Laminated Film | Z/AZ/ZM | ≥100 | / | 0T | 360 hours | / | / | / | 10 years |

Color Printed | Z/AZ/ZM | ≥25 | ≥100 times | 3T | 24 hours | 24 hours | 600 hours | 1000 hours | 10 years |

Texture, Suede | Z/AZ/ZM | ≥25 | ≥100 times | 2T | 24 hours | 24 hours | 1000 hours | 1000 hours | 10 years |

High Corrosion Resistant Polyester (PE.PRO) | Z/AZ/ZM | ≥25 | ≥1000 times | 3T | 120 hours | 120 hours | 2000 hours | 2000 hours | 15 years |

High Corrosion & Weather Resistant Polyester (HDP.PRO) | Z/AZ/ZM | ≥25 | ≥1000 times | 3T | 120 hours | 120 hours | 2500 hours | 3000 hours | 20 years |

Digital Empowerment Across the Entire Prepainted Steel Production Process

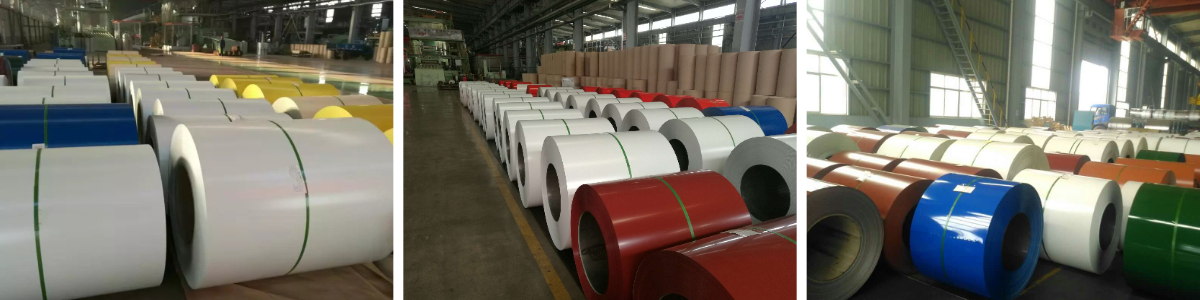

Xinghan Coating operates an integrated industrial chain covering pickling, rolling, galvanizing, and coating, with an annual production capacity of 3.7 million tons.

Through digital transformation and CMM certification, the company has integrated ERP, MES, and EPOS systems to connect every stage—from energy management and sales to production and delivery—enabling full-process traceability and supporting customized customer requirements.

The company runs two prepainted steel production lines, mainly producing mid-to-high-end building materials and home appliance color-coated panels. Designed by leading domestic engineering institutes, the lines use fully automated transmission and processing equipment, ensuring precise production control.

To enhance coating adhesion and surface quality, a multi-stage rinsing process is applied, significantly improving the finish of prepainted sheets. The production lines are equipped with high-efficiency fresh-air systems and waste-heat recovery units connected to the curing ovens, maximizing energy utilization and supporting environmental protection.

Xinghan Coating utilizes advanced prepainting equipment and adopts a double-coat, double-bake process, with an annual designed capacity of 300,000 tons.

Production Line Specifications

Production Line | Process | Substrate Types | Line Speed | Thickness (mm) | Width (mm) | Coil Inner Diameter (mm) | Designed Capacity (MT) |

Prepainted Line | Double-Coat Double-Bake | GI, GL, ZAM | 120 m/min | 0.12–1.0 | 650–1250 | 508 / 610 | 300,000 |

Color-Coated Sheet Weathering Tests

Outdoor exposure testing plays a crucial role in verifying the quality of color-coated sheets. The durability assessments conducted under natural environmental conditions provide results that no artificial simulation can fully replicate. By relying on real monitoring data collected from outdoor exposure sites, we ensure that our color-coated products deliver not only exceptional performance stability but also long-term reliability.

Through collaboration with raw material brands such as KCC, and by utilizing their extensive domestic and international exposure sites along with shared research data, Xinghan Coating continues to further optimize and enhance the quality of its color-coated products.